The Bend Navigator

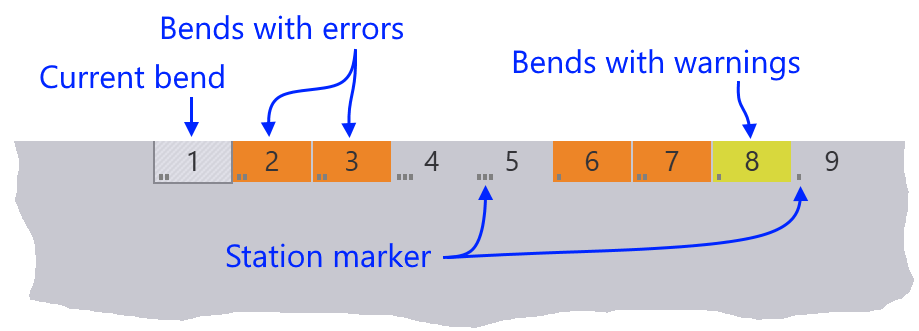

When you are in the bending view, the Bend Navigator panel appears along the top edge of the Flux window. This navigator provides a quick way to navigate through various bend operations, and also an instant view into various status-checks for every bend. It provides controls to view or stop the folding simulation. Here is an example of how the bend navigator looks:

The navigator displays different colors for bends that have some warnings or errors. The current bend is displayed with an outlined box, and the small dots[1] that appear in each of the boxes indicate the tool station in which the bend is processed.

Simulation Controls

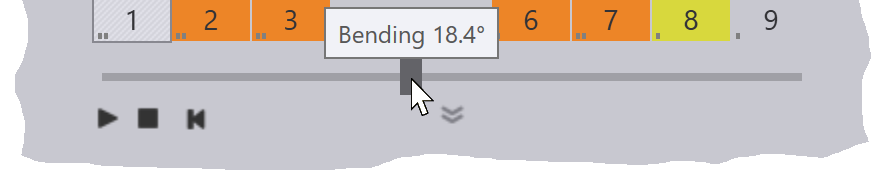

When you move the mouse near the fold navigator, simulation controls appear.

-

The slider can be used to move the current bend through various phases of the bending operation (insert part for bending, retract back-gauges move punch to pinch point, press with beam to bending position, etc). As the slider is moved, the tool-tip displays the current phase of bending, and various parts of the machine move in the simulation. If there are any collisions, those parts are colored red to clearly highlight the collision.

-

The play controls near the left can be used to start the simulation, stop it, or rewind to the beginning.

| You can also press the Spacebar to start or stop playing the fold simulation. |

-

The downward facing chevrons near the middle can be used to expand the fold navigator, displaying more detailed information about the errors and warnings for various bends.

| you can also press the Z key to expand/collapse the fold navigator display. |

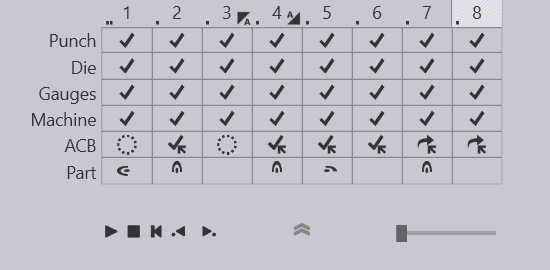

Bend Navigator: Expanded View

When you open the bend navigator by clicking the open button, or by pressing the Z key, this is how it looks:

For each bend, the navigator now displays a several rows of status icons. Each colored icon represents an error or a warning. Moving the mouse over the colored cell displays some more information about what the error or warning is (as you can see in the picture above).

Clicking on an cell that displays an error positions the simulation so that the error is immediately obvious. For example, clicking on a cell that displays a punch-crash error moves the simulation to the stage of the simulation where the punch crashes with the workpiece.

| Description | Meaning |

|---|---|

Punch |

Information about the upper tool used for the current bend. |

Die |

Information about the lower tool used for the current bend. |

Gauges |

The status of the back gauge positioning. |

Machine |

The status of the beam is displayed here. |

ACB |

ACB information is displayed here. |

Part |

Messages and directives on parts handling are displayed here. |

| Icon | Description |

|---|---|

|

Coining |

|

Double-sheet bending |

|

Hemming |

|

Post bend |

|

Pre-bending |

|

Skip bend |

|

Z bend |

The Punch Row

The Punch row of the bend navigator displays information about the punch used for this bend, and shows if there are any punch-related warnings or errors. These are the icons that you might see in the Punch row:

Icon |

Meaning |

|

No error, valid punch used |

|

Error: Punch collides with the part during bending |

|

Error: Punch collides with the Die during bending |

|

Error: Punch missing - no punch is assigned for this bend |

|

Error: Punch height is too short to complete the bend (a taller punch must be used, or an adapter added) |

|

Error: An incorrect punch process is used (for example, a non-coining punch is used for a coining operation, or a standard punch is used for a Z-bending operation) |

|

Error: Punch is overloaded beyond its rated tonnage (tooltip shows the actual load) |

|

Error: Punch span is too short (the part overhangs beyond the end of the punch) |

|

Warning: An ACB sensor is mounted at the end of the punch station |

|

Warning: ACB sensor disks are mounted too close to each other. |

|

This bend has been skipped (no processing for this bend) |

The Die Row

The Die row of the bend navigator displays information about the die used for this bend, and shows if there are any die-related warnings or errors. These are the icons you might see in the Die row:

Icon |

Meaning |

|

No error, valid die used |

|

Error: Die collides with part during bending |

|

Error: Die collides with Punch during bending |

|

Error: Die missing - no die assigned for this bend |

|

Error: An incorrect die process is used (for example, a standard V die is used to process a Z-bend) |

|

Error: Die is overloaded beyond its rated tonnage (the tooltip shows the actual tonnage) |

|

Error: Die span is too short (the part overhangs beyond the end of the die) |

|

Warning: The flange might be too narrow for this die; the bending may not be accurate |

|

This bend has been skipped |

The Gauges Row

The Gauges row of the bend navigator displays information about the back-gauges used to reference the part during bending, and also any gauge-related warnings or errors.

Icon |

Meaning |

|

No error, valid die used |

|

Error: The back-gauges collide with the part |

|

Error: The back-gauges collide with the punch or the die |

|

Error: Back-gauges not assigned for this bend |

|

Error: Back-gauge position exceeds the travel limits of the gauge |

|

Warning: Only one back-gauge used; gauging may not be stable |

|

Warning: Back-gauge position well above or below die-line; gauging may not be stable |

|

This bend has been skipped |

The Beam Row

The Beam row of the bend navigator displays errors related to the beam (press-ram).

Icon |

Meaning |

|

No problems related to the beam |

|

Error: Part collides with the press beam during bending |

|

Error: Part collides with the bend-guard (safety system) during bending |

|

Error: Machine’s rated tonnage exceeded while processing this bend |

|

This bend has been skipped |

The Die-Bed Row

The Die-Bed row of the bend navigator displays errors related to the die-bed and table.

Icon |

Meaning |

|

No problems related to the die-bed |

|

Error: Part collides with the die-bed or machine table during bending |

|

This bend has been skipped |

The ACB Row

The ACB row of the bend navigator displays warnings and errors related to the angle measurement system.

Icon |

Meaning |

|

ACB Identify method used for this bend |

|

ACB Corrected method used for this bend (user-specified spring-back correction) |

|

ACB Learned method used for this bend (beam bending stroke copied from earlier reference bend) |

|

ACB is not used for this bend |

|

Warning: No ACB disks are engaged with the part |

|

Error: ACB sensor disks falls into a hole |

|

Warning: Flange is too narrow for ACB measurement |

|

Error: Incorrect bend is picked as the reference bend for ACB |

|

This bend has been skipped |

The Handling Row

The Handling row of the bend navigator displays information about part-handling. This includes information on how the part should be rotated or flipped between bends, and also warnings for situations where the part center-of-gravity falls behind the bending axis (part tip-back warning).

Icon |

Meaning |

|

No part handling issues; part does not have to be rotated or flipped |

|

Error: An invalid bend sequence is used; the segments of this bend are not collinear and this bend cannot be processed at this position in the sequence. |

|

Warning: Part flanges collide during over-bending; angle accuracy may be compromised |

|

Warning: Part center-of-gravity lies behind the bend line (part tipping backwards) |

|

Part has to be rotated left for the next bend |

|

Part has to be rotated right for the next bend |

|

Part has to be rotated 180° for the next bend |

|

Part has to be flipped upside down for the next bend |

|

This bend has been skipped |

As you make changes to the punch, die, sequence, or gauge configurations, the bend navigator is immediately updated with the new status. This immediate feedback makes it easy to experiment with different configurations without having to issue a recompute command each time.