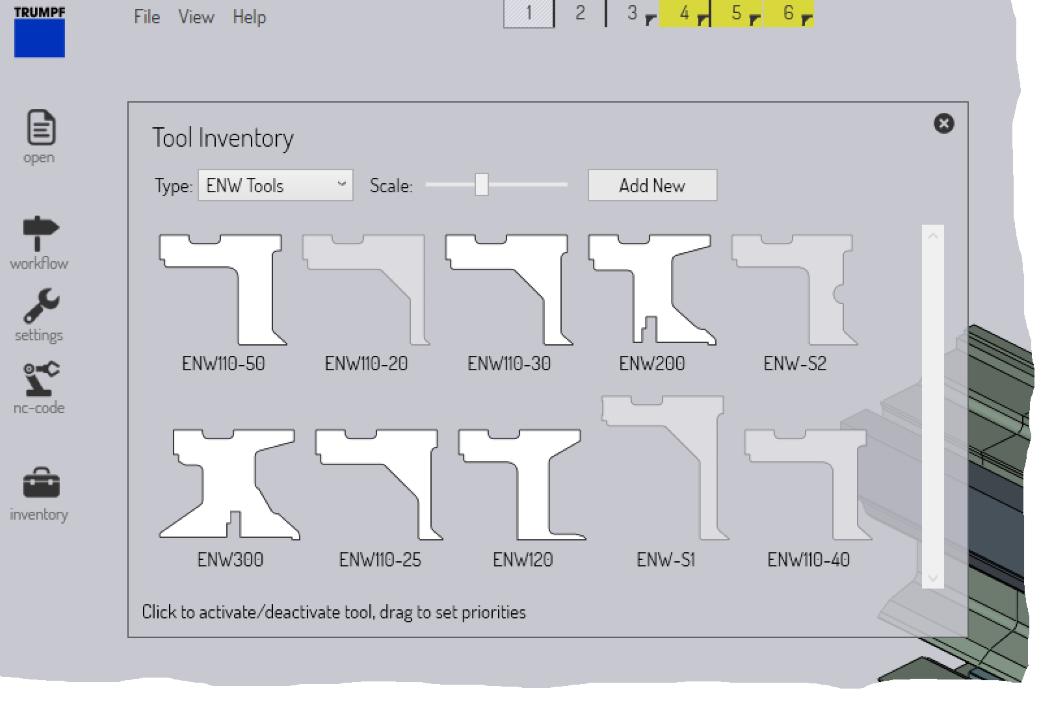

Tool Management

There is a wide variety of optional ENW blank-holders, and ZBW blades that you may use with your panel bender. In addition, some of the components of the panel-bender such as the upper or lower blank-holder, and the folding blades may be swapped out with different ones. The Tool Inventory window in Flux is used to configure these attachments and tools for the panel-bender.

To access the Tool Inventory window, open a part, and switch it to panel bending mode. An inventory button appears in the command bar, and clicking on this opens up the Tool Inventory window.

Editing ZBW blades or ENW tools

Use the Type selector to pick the ENW tools or ZBW blades that are available for Flux to use. When editing these tools, clicking on a tool toggles between being available or unavailable. In addition, you can rearrange these tools in a diferent order (by clicking and dragging a tool to a different location). Flux uses this ordering as the tool priority, and tries to use these tools in the specified order. For example, in the image above, Flux will try to process a part using the ENW110-50 tool before it tries to use the ENW110-30 tool.

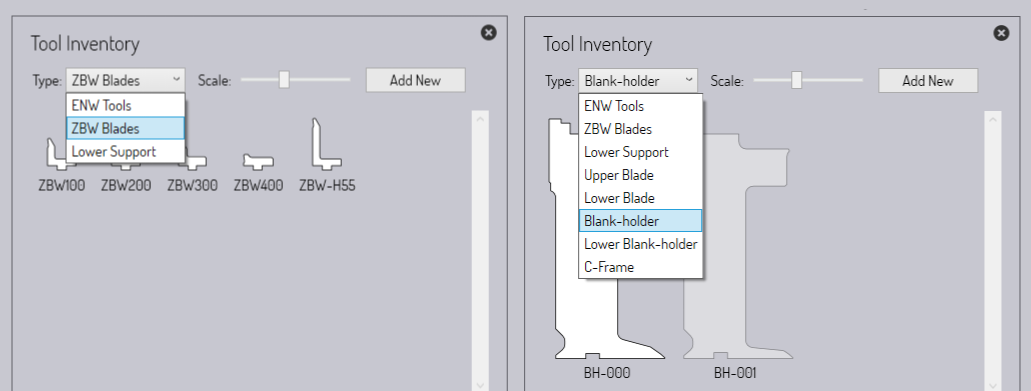

Editing machine-configuration

Some of these types (like the blank-holder, upper-blade, or lower-blade) do not allow multiple-selections. In a sense, these types represent the current configuration of the machine, and only one blank-holder may be mounted on the machine at one time. When the upper or lower blade is changed on the machine, for example, this section is used to inform Flux of the change, so it can tool up parts and do collision checks appropriately.

Depending on your Flux installation, it is likely that these sections (like blank-holder, upper-blade or lower-blade) may not be accessible for editing except by a Trumpf technician. The image below shows the typical settings available for editing (on the left), and the additional settings that may be avialable to Trumpf technicians (on the right).

All these settings are for the currently selected panel-bender (the one being used for the current part). If you have multiple panel benders, you can vary these settings individually for each one.

Importing new tool data

When you get new tools from Trumpf, these will be accompanied by tool-data files (tdata files), that are used to inform Flux about the geometry and capabilities of these new tools. You can import these new tdata files into Flux using the Add New button. This opens a file selector that lets you select one or more tdata files. These then get added to the tool catalogue, and can then be selected in the various pages of the Tool Inventory window.