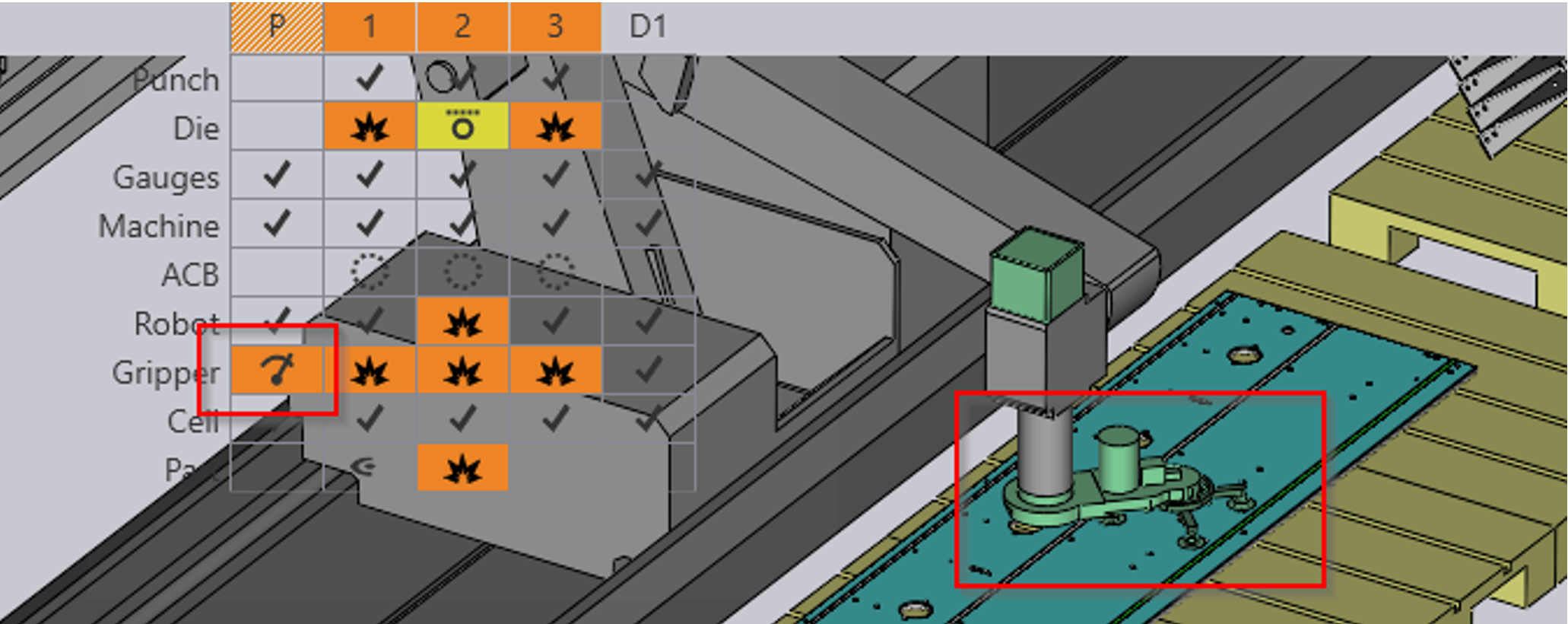

Part Pickup Error

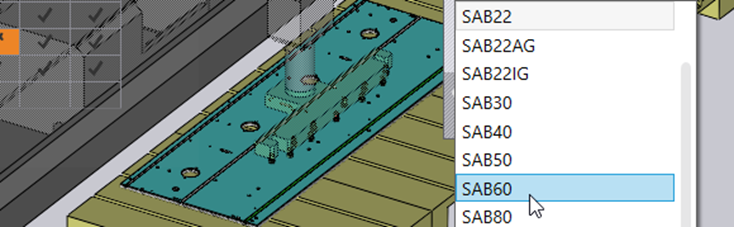

Selecting the suitable Gripper

The selection of a suitable gripper is crucial for a good overall bend process. Flux RoboBend will select a suitable gripper but if gripper force overloads and collisions in the later process affect the solution, you might think of changing the gripper or designing a new one.

Changing the Gripper based on loading factor

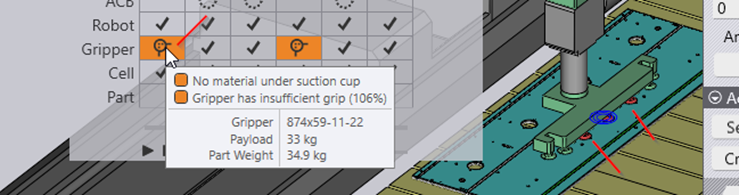

-

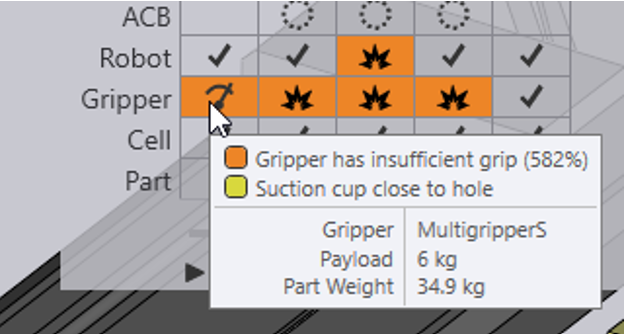

In the shown example a too small gripper was selected which is overloaded by a factor of 5.

Using larger and sufficient suction cup Gripper

-

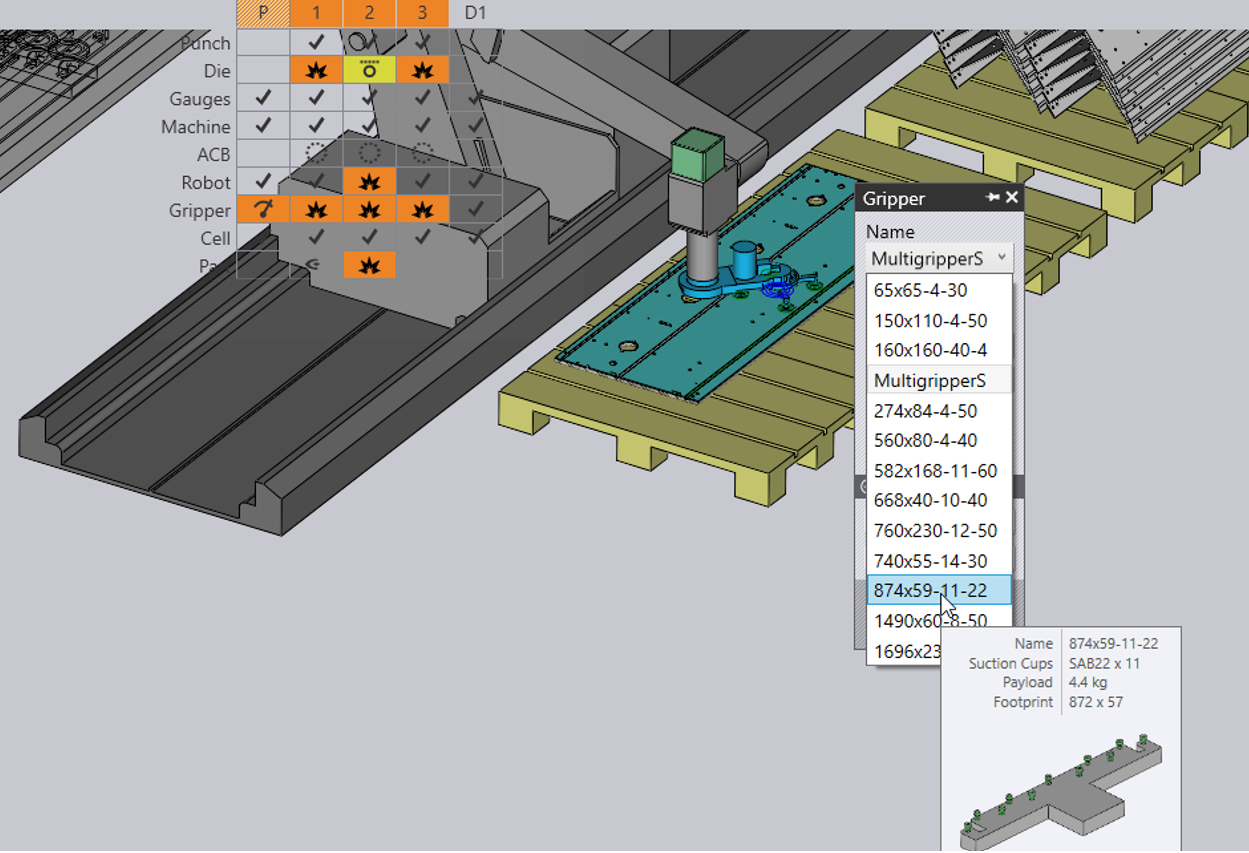

Changing the gripper with one which has more suction cups will be a first good step. With a more eccentric gripper many collisions already resolve.

-

To get more process stability you might even use larger suction cups with this gripper.

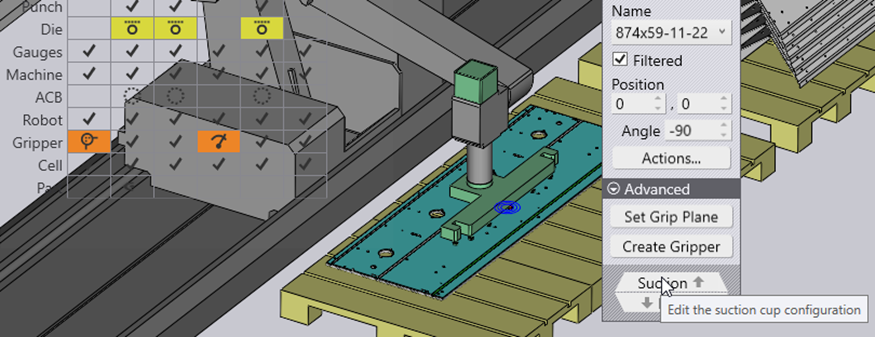

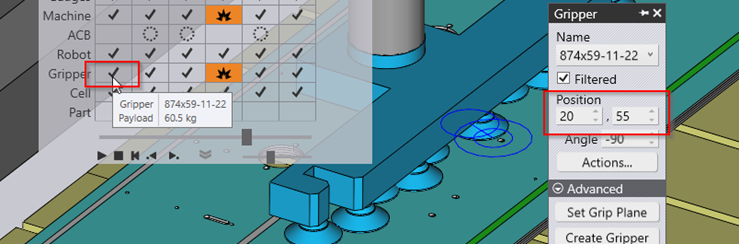

Changing Gripper to handle holes on part

-

The part has many holes which prevent a proper vacuum.

-

To resolve this you have to move the position of the gripper on the part.

-

In this position has enough vacuum and the issue is resolved.