Optimizing Tilting Behaviour

Applying Microjoints based on Tilting Calculations

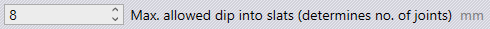

The user can define hierarchical finishing rules that will determine how contours are finished. Whether they are microjoint, scrap-cut or left free on the table.

| Option | Description |

|---|---|

None |

No special action is taken |

Auto microjoint |

Applies microjoint(s) on the contour. Software will

automatically decide how many microjoints are required based on the

parameter. |

Cut up scrap |

Cut up the contours into smaller pieces so that they fall through the slats. |

One microjoint |

Create exactly one microjoint on the contour. |

Two microjoints |

Create exactly two microjoints on the contour. |

Three microjoints |

Create exactly three microjoints on the contour. |

Eliminating Holes that can cause a Tilt

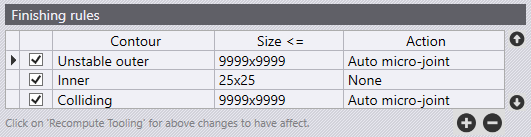

Using the finishing rules suggested above, the user can decide to scrap-cut holes that can collide with the machine head. Flux will automatically apply this rule and create scrap tooling, where necessary, when loading the part into the job.

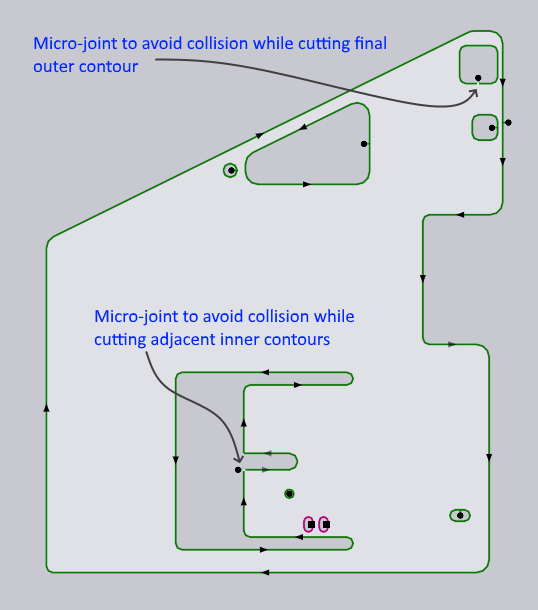

Determine Number of Required Microjoints

Flux can determine the number of microjoints required on a contour (based on contour geometry, slat configuration, material, thickness, and gas pressure). Usually, one microjoint is enough, but in some cases (typically, long but thin contours), more microjoints might be required to provide enough support to the contour so that it does not bend down too much into the slats (or even break the microjoint) due to the torque created by its own weight or gas blowing over it.

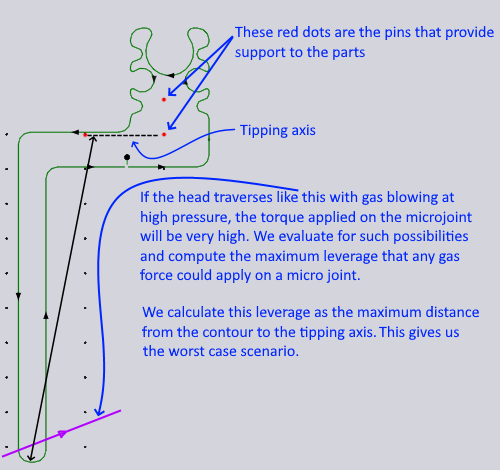

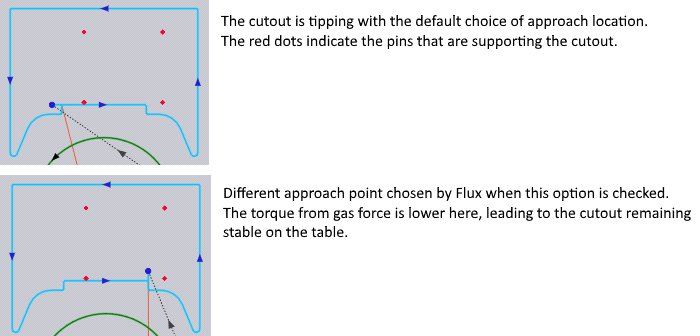

Automatic Movement of the Approach Point to avoid Tilting

Sometimes choosing a different approach point can change an unstable contour into a stable contour. Flux can detect such situations and automatically adjust the approach point.

Process Stability

The process stability is influenced mainly by:

-

Tilting parts that might tip up and collide with the cutting head.

-

Thermal tensions that bend parts up and collide with the cutting head.

Parts that are a risk are highlighted in red in the sequencing overview.

A common approach to increasing process stability, for example are microjoints and scrap cutting.