Basic Workflows

Flux Cut

Flux Cut is a sheet-metal cutting software for Laser machines.

A 2D sheet metal flat can be cut using a high power laser before it is sent to a press-brake or panel bender for further processing. Here is some of the work that Flux Cut can do:

-

Compute a feasible and optimal cutting sequence.

-

Compose cut tooling stations from the available inventory of laser tools.

-

Compose several different nesting operations.

-

Generate NC Code that can be transmitted to the laser machine for cutting.

-

Generate reports for the cutting process.

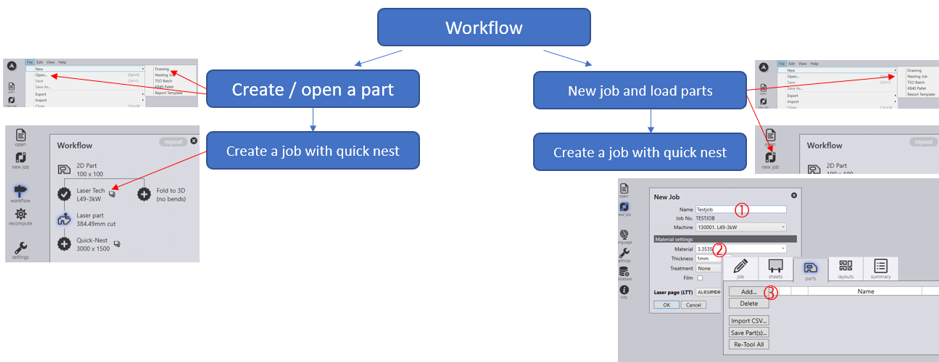

Workflow Types

-

Part workflow focuses on producing a single part.

-

Job workflow focuses on producing different parts in a nest.

Part Workflow

-

Click on the Workflow icon

in the command bar on the left to open the workflow panel.

in the command bar on the left to open the workflow panel. -

Click on the Laser Tech process node in the workflow panel.

-

Click on the Quick Nest process node.

-

Click the close button to close the workflow panel.

Here is a faster way to do the above steps, using keyboard shortcuts:

-

Press W to open the workflow panel.

-

Press L to switch to Laser tech.

-

Press N to do quick nesting.

-

Press Esc to close the workflow panel.

Job Workflow

-

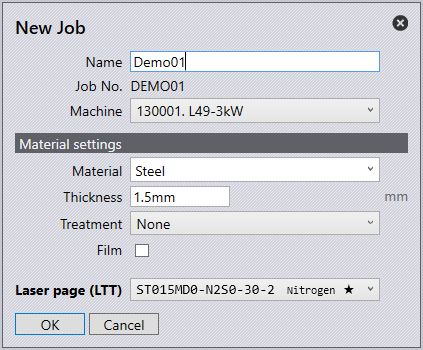

To start a new job, select the New Job icon found on the left side of the launch screen or press Alt F N J.

-

Fill in the Name and Job No. for the given job.

-

The Machine drop-down menu will display the available machine list to run the job.

-

The Material drop-down menu will display the available materials to run the job.

-

The Thickness option is to specify the thickness of the sheet.

-

The Treatment drop-down menu is to specify whether the material has any treatment.

-

Select the Film checkbox if the material has a protective film.

-

The laser page (LTT) drop-down is to select a technology table to use, this is useful if you wish to switch between different gas types on the machine.

-

Click OK to see pages for Job, Sheets, Parts, Layouts, and Summary settings.

Keyboard shortcuts:

Job |

I |

Sheets |

S |

Parts |

P |

Layouts |

L |

Summary |

U |