Editing the Blank-holders

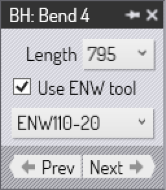

Clicking on the blank-holder brings up the BH panel (blank-holder panel). The blank-holder panel has the following settings:

-

Length is used to select different blank-holder composition length (this is displayed if this side uses a split-blank holder composition).

-

The Use ENW tool check-box is used to enable an ENW tool for processing this bend.

-

If the Use ENW tool setting is turned on, then this list can be used to select one of the available ENW tools. This is a part-wide setting, since different ENW tools cannot be used for different bends.

-

The Prev and Next button are used to switch between the different bends in the part.

As you experiment with various ENW tools, Flux will immediately compute the collision status of that blank-holder composition for all the bends in the part, and will update the Fold Navigator status. Thus, it is very simple to pick a suitable ENW tool by scrolling through this list, since there is immediate feedback on whether any bends have issues with the selected tool.