Pickup from a Pallet

When a vacuum suction or magnetic gripper is used, blanks (un-bent flats) are typically picked up from a pallet. Various settings are used to control the pickup process:

-

The position of the pallet in the machine cell.

-

The position and orientation of the part stack on the pallet.

-

The position and orientation of the suction gripper on the part.

-

The suction cup configuration of the gripper (which cups are turned ON/OFF, and what type of cups are mounted in each socket).

-

The areas of the part that are captured by the camera on the robot, and used as references for calibrating the part’s position.

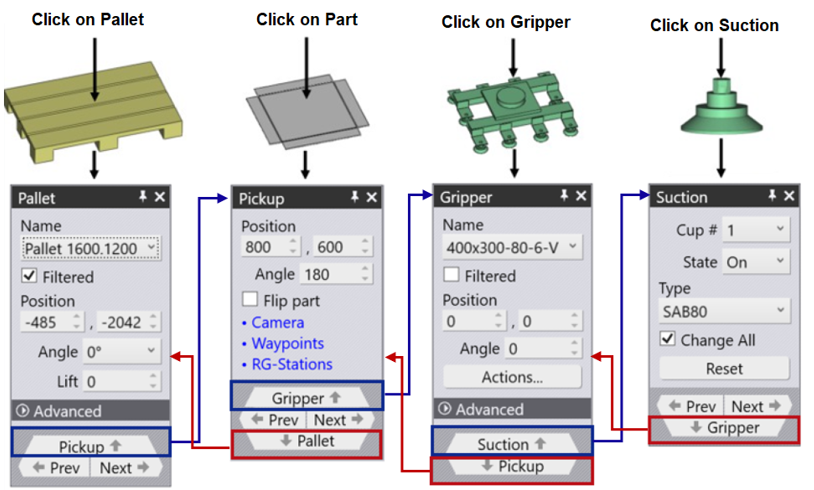

Like most of the interface in Flux RoboBend, these settings are all viewed and edited using respective panels. Most of these panels can be accessed by just clicking on different objects displayed on the screen, in a very intuitive manner.

-

To open the Pallet panel, click on a pallet.

-

To edit the part-pickup on a pallet (the Pickup panel), click on the blanks lying on the pallet.

-

To edit the gripper position on the blank (the Gripper panel), click on the gripper.

-

To edit the suction cup configuration of a gripper (the Suction panel), click on one of the suction cups.

-

To edit the imaging positions (used by the fine-position recognition system), click on the camera.

In addition, all these panels have navigation buttons ![]()

![]()

![]()

![]() leading to the other panels in a logical sequence.

leading to the other panels in a logical sequence.

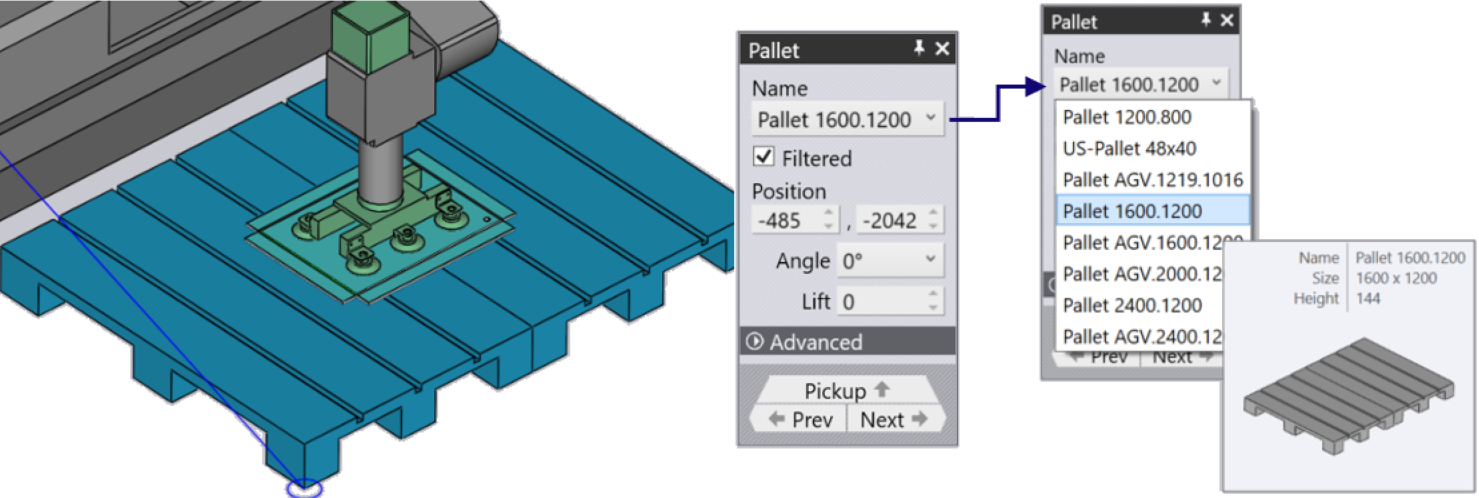

Pallet Panel

The Pallet panel is used to select a pallet and position it in the cell. You can open this panel by just clicking on a pallet; Flux RoboBend will also position the simulation timeline so that the robot is posed at the point of picking up the part from the pallet.

-

Use the position inputs to place the pallet in the cell within the required position,

-

use the Angle input to rotate the pallet.

-

use the Lift option to mark the pickup height form the pallet. As you move or rotate the pallet, the part stack on the pallet, and the gripper/robot all follow the movement.

-

Use the Advanced option to save the last modified configuration of the modified cell.

-

Use the Next and Prev buttons to navigate to the other pallets in the cell; for example the pallet with the part-unload positions.

-

Use the Pickup navigation button to edit the position of the part-stack on the pallet.

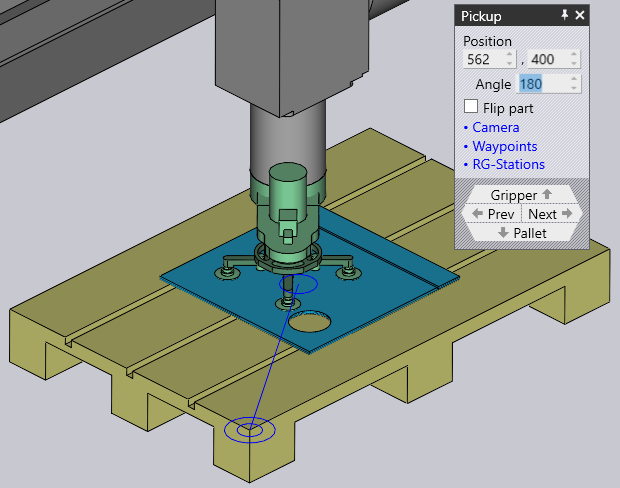

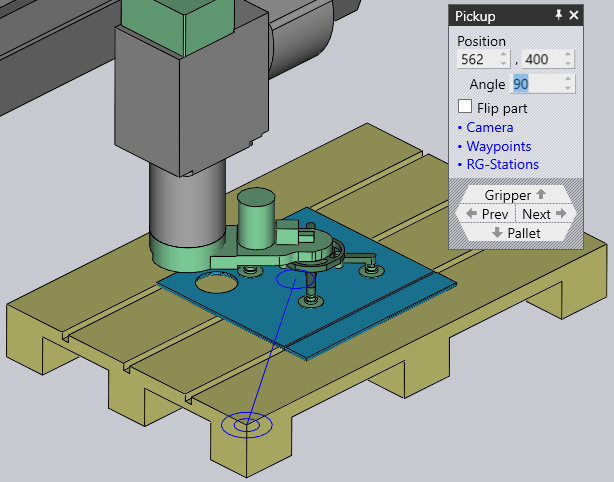

Pickup Panel

The Pickup panel is used to edit the position of the part-stack on the pallet. You can open this panel directly by clicking on the stack of blanks lying on the pallet. You can also access it using the Pickup navigation link from the Pallet panel.

-

Use the position inputs to place the pickup position on the pallet in the cell; these coordinates specify the center of the part, relative to the corner of the pallet, and are in the pallet’s local coordinate space.

-

Use the Angle input to rotate the part around in the pallet.

-

Select the Flip check box to flip the part over.

| An additional regrip operation is necessary to flip the part before the first bend can be processed. |

As the part is moved around on the pallet, the gripper remains stuck to the part and the robot follows the movements.

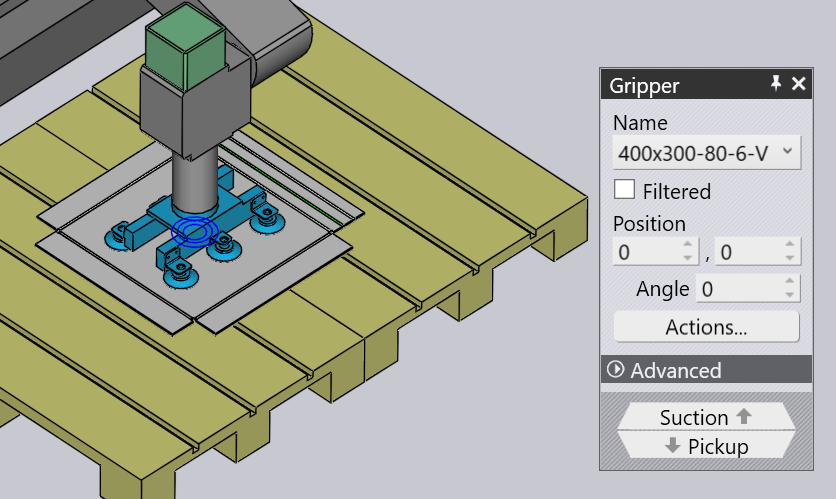

Gripper Panel

The Gripper panel is used to select a different gripper, or to change the position and orientation at which the gripper picks up the part. You can also access it using the Gripper link from the Pickup panel.

-

Use the Name drop down list to select a different gripper. Normally, only grippers suitable for this part are displayed (based on gripper size and payload), but you can turn off the Filter check and then all the grippers are listed.

-

Moving the mouse over a name in the grippers list displays a summary of that gripper, along with a thumbnail

-

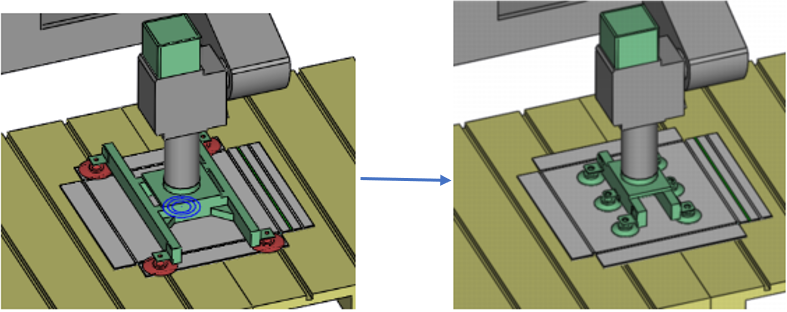

Automatically the Gripper from the list is selected which can be used for the part provided. But you need to check if the selected Gripper best suits our requirement

-

The image below is an example where the selected gripper is not holding the part properly and going out of the part boundary which is indicated by the color of the suction in red. Then the proper gripper was selected and color of the suction cups also turned to green.

-

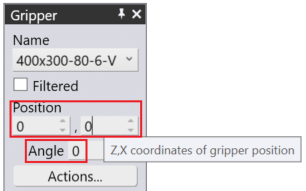

Use the Position inputs to move the gripper-center relative to the part-center along the Z & X direction, and use the Angle input to rotate the gripper, relative to the part’s orientation.

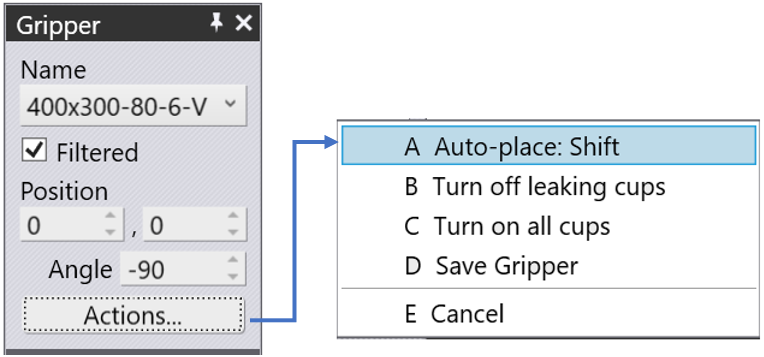

Actions.. option helps to:

-

A Auto-place: Shift - Keyboard shortcut key A helps to place the Gripper over the part

-

B Turn off leaking cups - Keyboard shortcut key B helps to turn off the suction cups which are not working properly/ considered as leaking cups

-

C Turn on all cups - Keyboard shortcut key C helps to Turn ON all cups

-

D Save Gripper - Keyboard shortcut key D helps to Save the Gripper with the last modified cup positions.

-

E Cancel - Keyboard shortcut key E helps to cancel the changes on this Gripper setup.

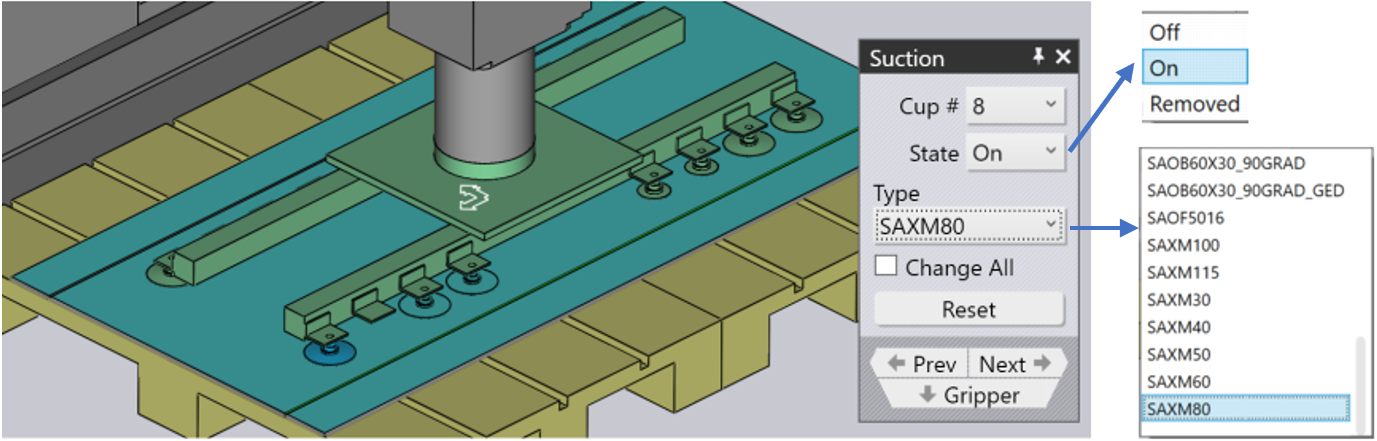

Suction Panel

The Suction panel is used to configure the suction-cup layout of a gripper. You can open this panel by clicking directly on a suction cup, or by choosing the Suction link from the gripper panel.

-

Use the Cup # choice to select a particular suction cup in the gripper, or use the Next and Prev buttons to navigate through the suction cups. The selected suction cup is highlighted in blue and can be edited.

-

Use the Type panel to change to a different type of suction cup. Usually, one changes all the suction cups in a gripper to the new type, but you can also mix-and-match suction cups by turning off the Change All button and then changing the suction cups.

| The choice of suction cups will be restricted, since all the suction cups mounted on a gripper frame must have the same working height. The image above shows two of the suction cups replaced with smaller ones (SAXM50, instead of the default SAXM80). |

-

For each suction cup, you can choose between three states - On, Off or Removed. See the description below for more details on this.

-

Use the Reset button to restore the gripper back to its original state - all suction cups are turned on, and are reset back to the default cup type that is defined in the gripper.

The default state for a suction cup is On, which means the suction cups is connected to the vacuum line, and helps in lifting.

If a suction cup lies over a hole in the part, you can change the state to Off, which means no vacuum. (This reduces the lift of the gripper, and changes the center-of-lift, which Flux RoboBend takes into account to do gripper capacity checks).

| The cup is still mounted in the frame, and participates in collision checks. Flux RoboBend displays switched-off suction cups as wireframes, as you can see with two of the suction cups in the image above. |

Finally, you can set a suction cup state to Removed, which means the cup has been removed from the frame in the actual machine. There is no lift from this cup, and it will not cause a collision. This is sometimes useful if a cup falls over a formed region, or causes a collision with the die or machine table during operation.

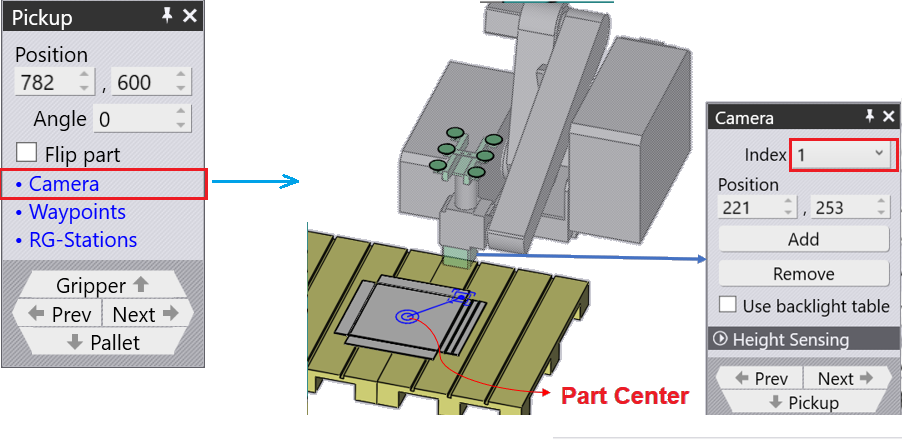

Camera Panel

The pickup process requires one or more images to be captured by the camera, and an image-processing system uses these images to estimate exactly where the part is on the pallet.

-

Clicking on the camera mounted on the robot, or choosing the Camera navigation button from the Pickup panel opens up the Camera panel. Flux RoboBend also positions the simulation so the robot is in the pose required to capture the image.

-

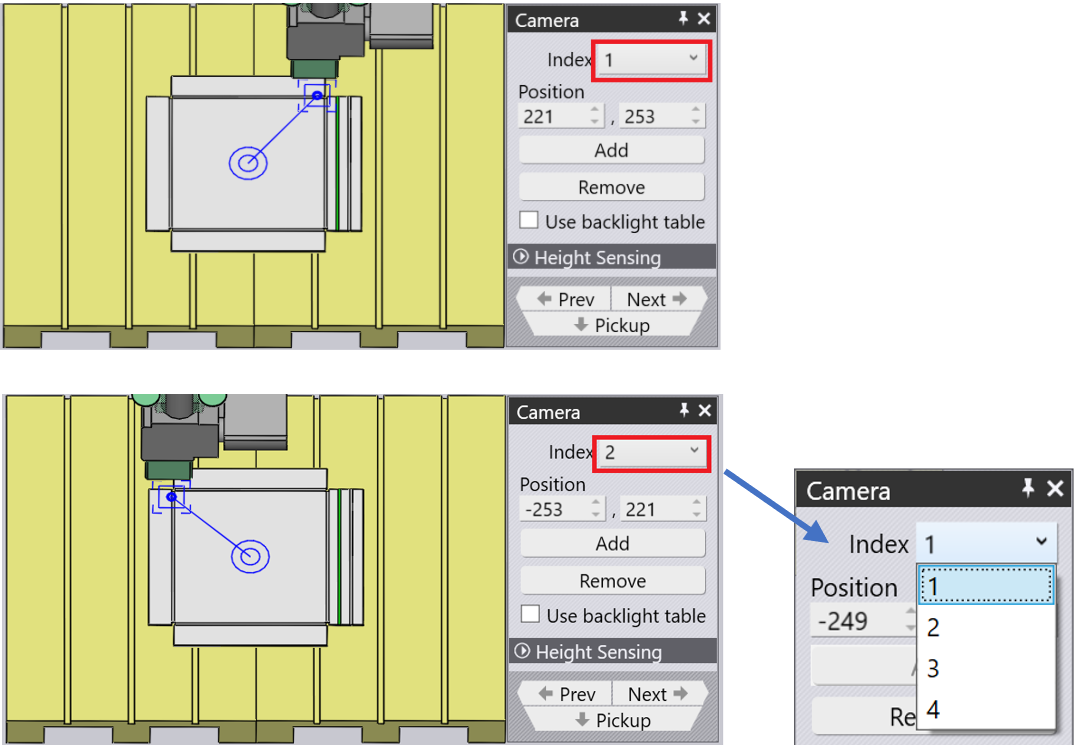

Use the Index list to move through the various fine-recognition images being used for this part. As you do this, Flux RoboBend displays a blur outline that shows the image-recognition zone on the part.

-

Use the Position inputs (Z and X direction) to re-position this zone, to better include some features of interest that can improve the recognition accuracy.

-

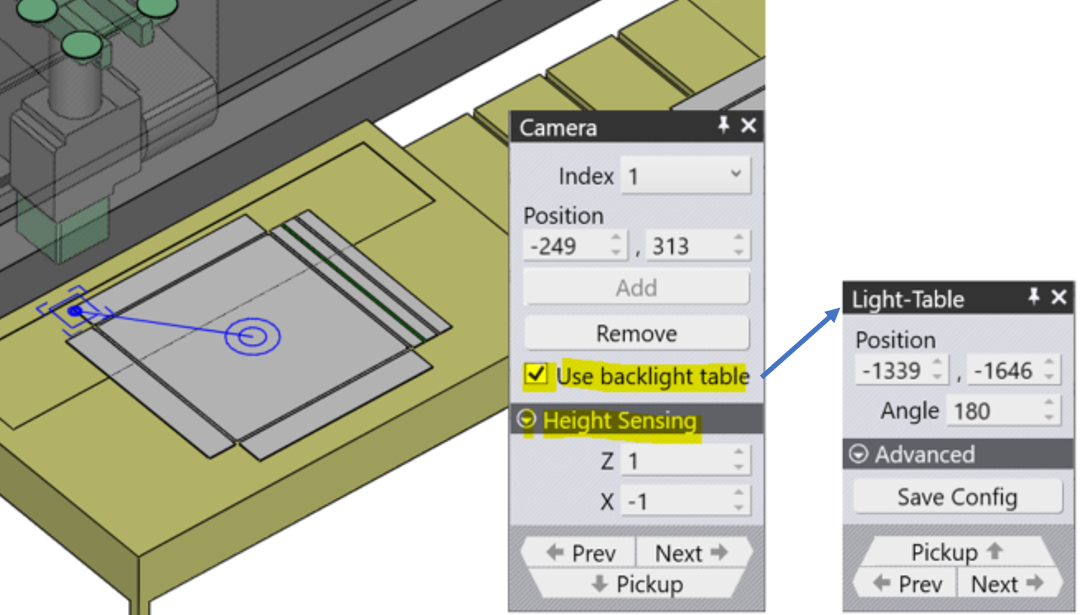

Use the Add button to add an additional recognition image (up to 4), and use the Remove button to remove the current recognition image. During the simulation of the part-pickup, Flux RoboBend shows the robot moving to each of these recognition areas with the camera down and pausing to acquire the image.

In the image placed on the right, Index numbers 1 & 2 defines the corners of the part to be measured using the camera before the Pickup process.

Also the Use backlight table option is used to place the part and check the actual dimension.

The Light-Table can be placed in a desired position by clicking the mouse over and positioning with the Z & X values along with the Angle input.

Height Sensing option helps in positioning the sensor point in Z and X direction.