Part Pickup

The BendMaster has two different mechanisms for part pickup and gripper usage, depending on whether we are processing small parts or large parts. In general, small parts (less than 200 x 300 mm) are processed using a mechanical jaw gripper, and are picked up from a blank dispenser. Larger parts are processed using vacuum suction or magnetic grippers and are picked up from pallets.

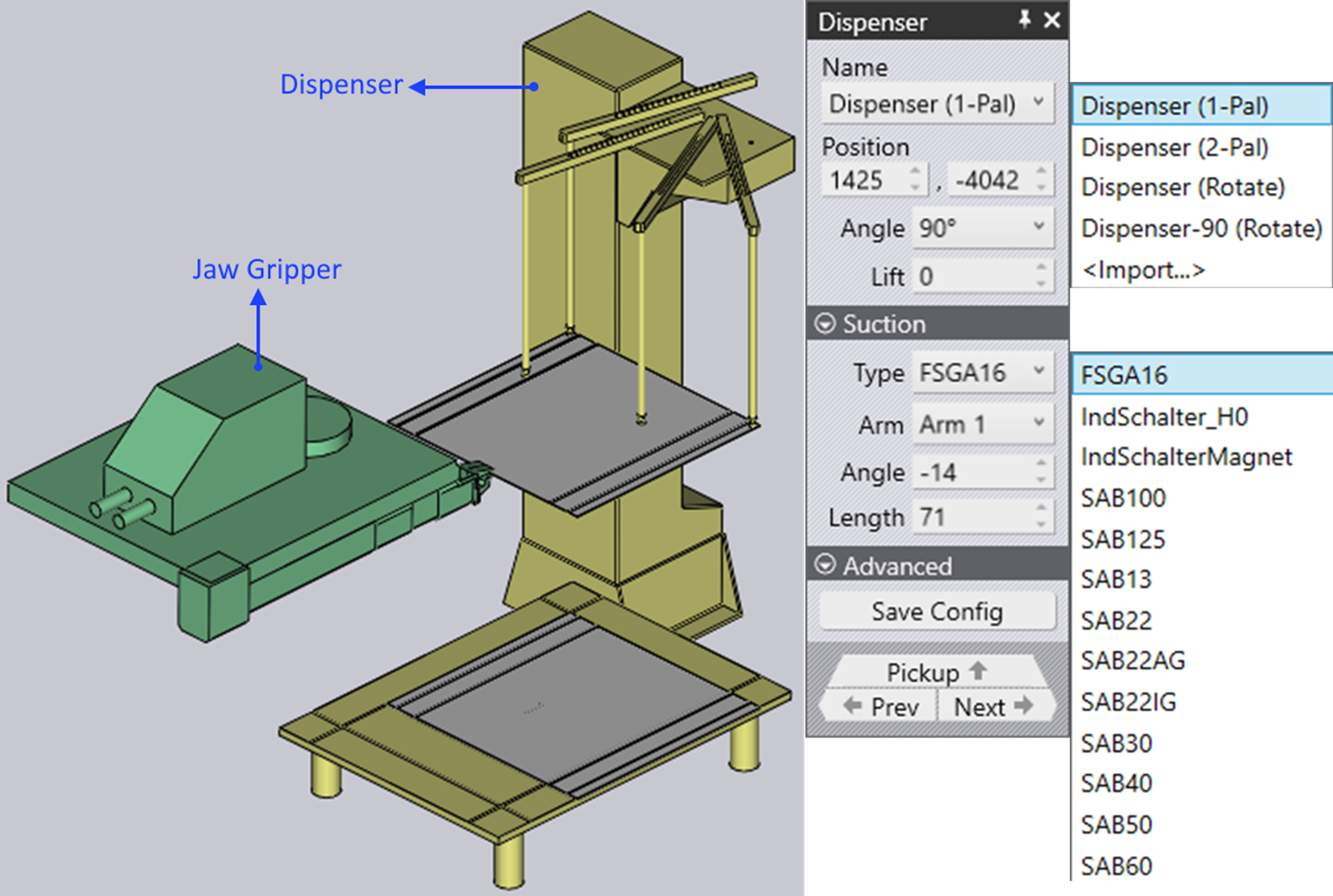

Figure 1. Blank Dispenser

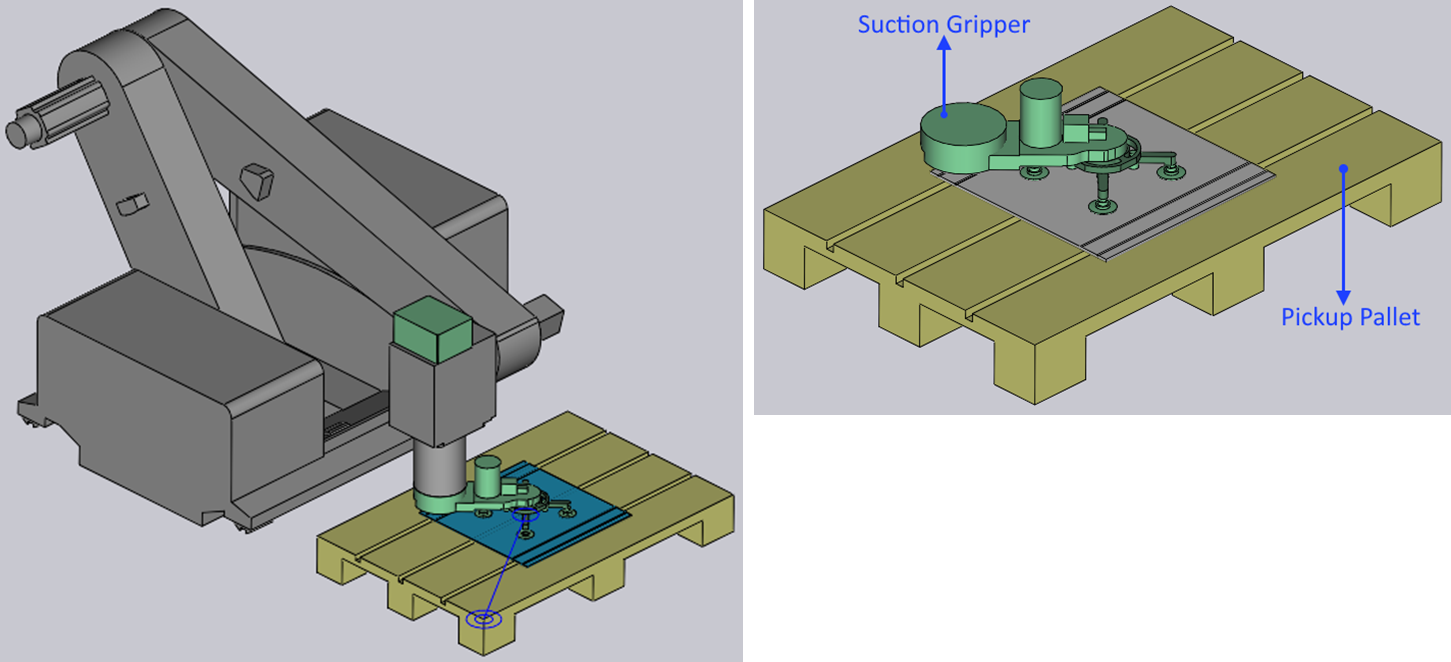

Figure 2. Robotic arm with suction gripper

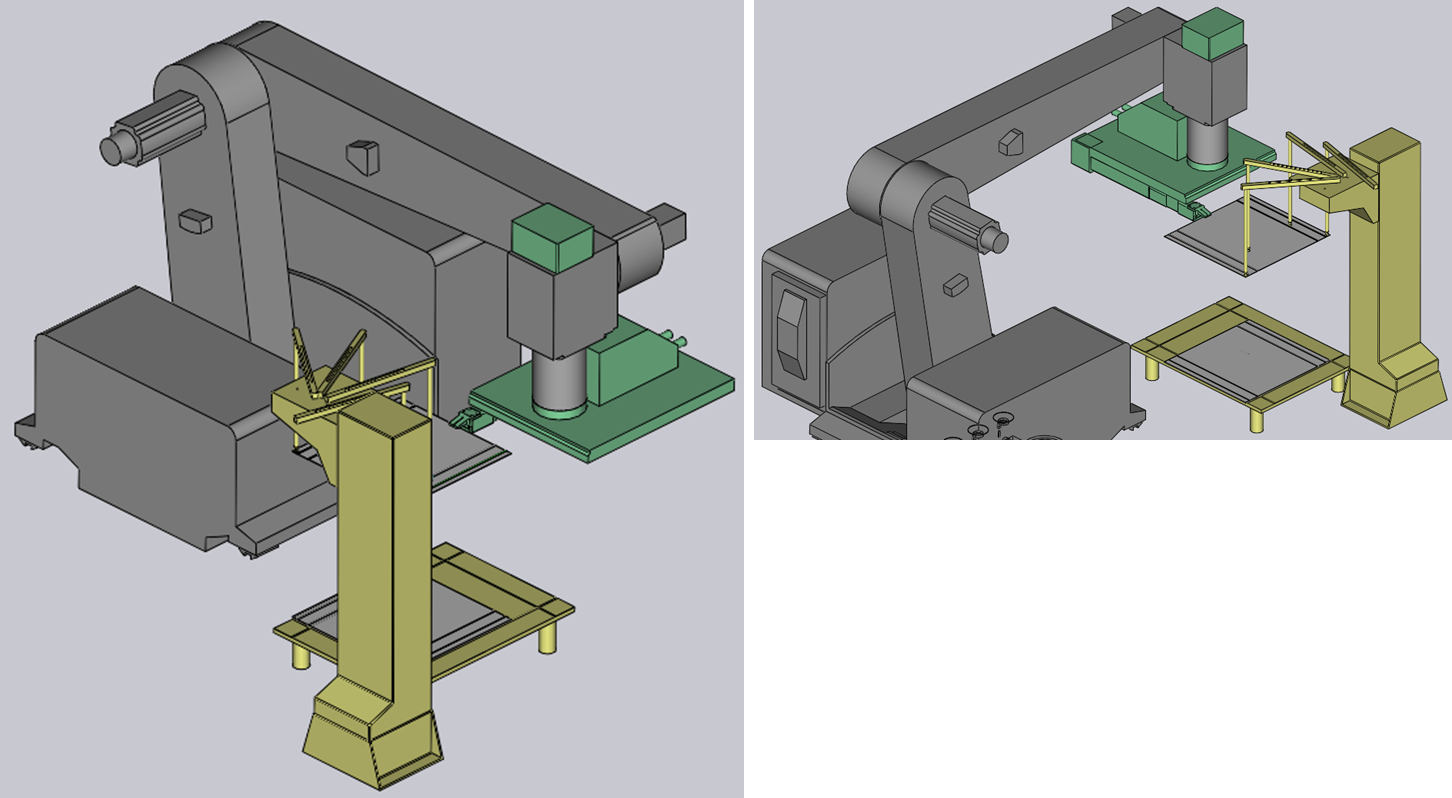

Figure 3. Robotic arm with jaw gripper

Depending on your gripper inventory, Flux RoboBend can automatically determine the optimal processing mode for a part. The handling type you choose will determine how you modify the part pickup after that.