Create/ Edit a Gripper

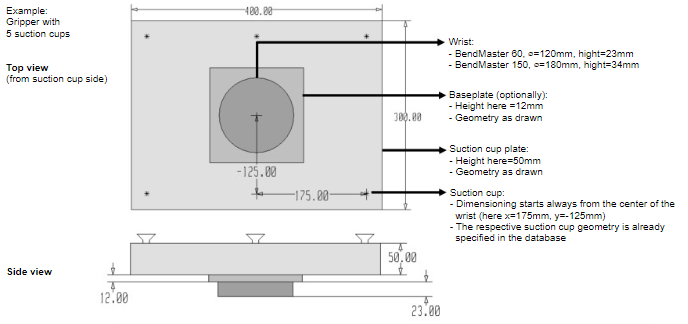

To create an individual gripper, data of the wrist, the optional base plate, the suction plate, and the suction cups, with the corresponding positions are required.

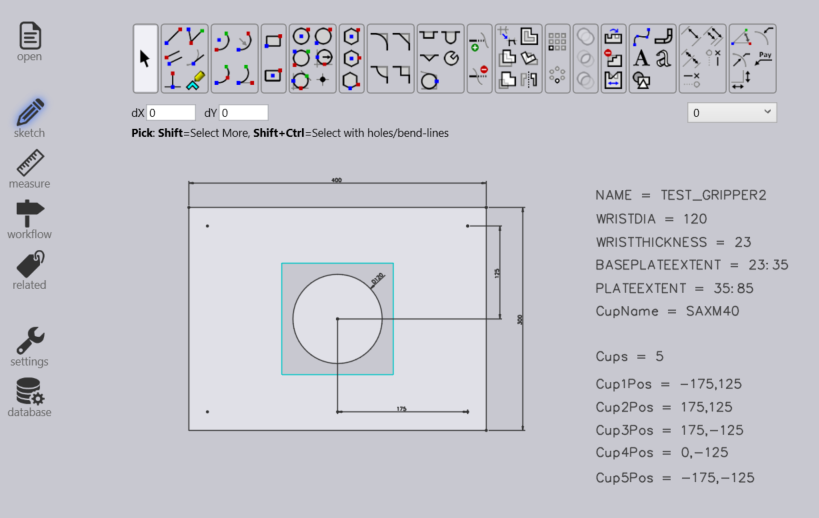

For this purpose a DXF file, including the respective geometry and parameters can be created.

Create your own gripper geometry with the desired suction cups, using the drawing module. Alternatively, an existing DXF drawing can also be imported and edited.

Procedure:

-

Open a new drawing inside Flux and select the sketch option.

-

Create a drawing of the gripper with the wrist, base plate and suction cup plate and enter (alternatively, open an existing DXF drawing and adapt it as required). C:\ProgramData\Metamation\Flux\BGrippers\

-

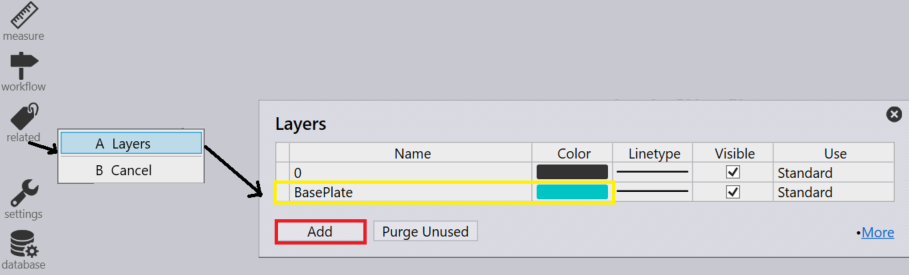

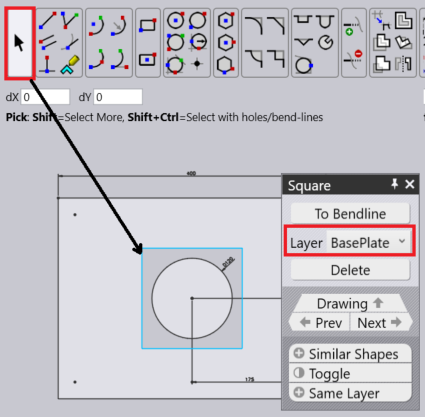

Apply a different colour (e.g. cyan) to the contour of the base plate.

-

For a correct graphical display of the optional base plate, it must be stored in a separate layer. In the drawing module with the entry BasePlate at the corresponding colour (here cyan), the necessary layer can be define.

-

Make sure that the centre of the wrist is at the drawing zero point and input the required text inputs for the parameters.

-

Many of the settings for this gripper come from text entities that are of the form KEY=VALUE. Here are the possible keys, with their meanings

| key | Meaning |

|---|---|

Name |

The name of the gripper |

Weight |

Weight of the gripper, in kg. |

WRISTDIA |

Wrist diameter (must be 120/180 corresponding to BM60/BM150) |

WRISTTHICKNESS |

The thickness in Z of the wrist cylinder underneath. The wrist cylinder extends from Z=0 to this value |

PLATEEXTENT |

The Z extent (in the form ZMIN:ZMAX) of the plate. Typically, one sets ZMIN the same as WRISTTHICKNESS, so the plate starts where the wrist-cylinder ends. |

BASEPLATEEXTENT |

The Z extent of the baseplate (see the section below on Two-Layered-Grippers) |

CUPNAME |

The type of suction cup used for this gripper (like SAXM50) |

CUPS |

The number of suction cups |

CUP1POS |

The position of the first suction cup in the form X,Y |

CUP2POS |

The position of the second suction cup |

CUPNPOS |

The position of the Nth suction cup |

CUPDIA |

Can be used instead of CUPNAME to specify a suction cup (not recommended). |

Key |

Meaning |

-

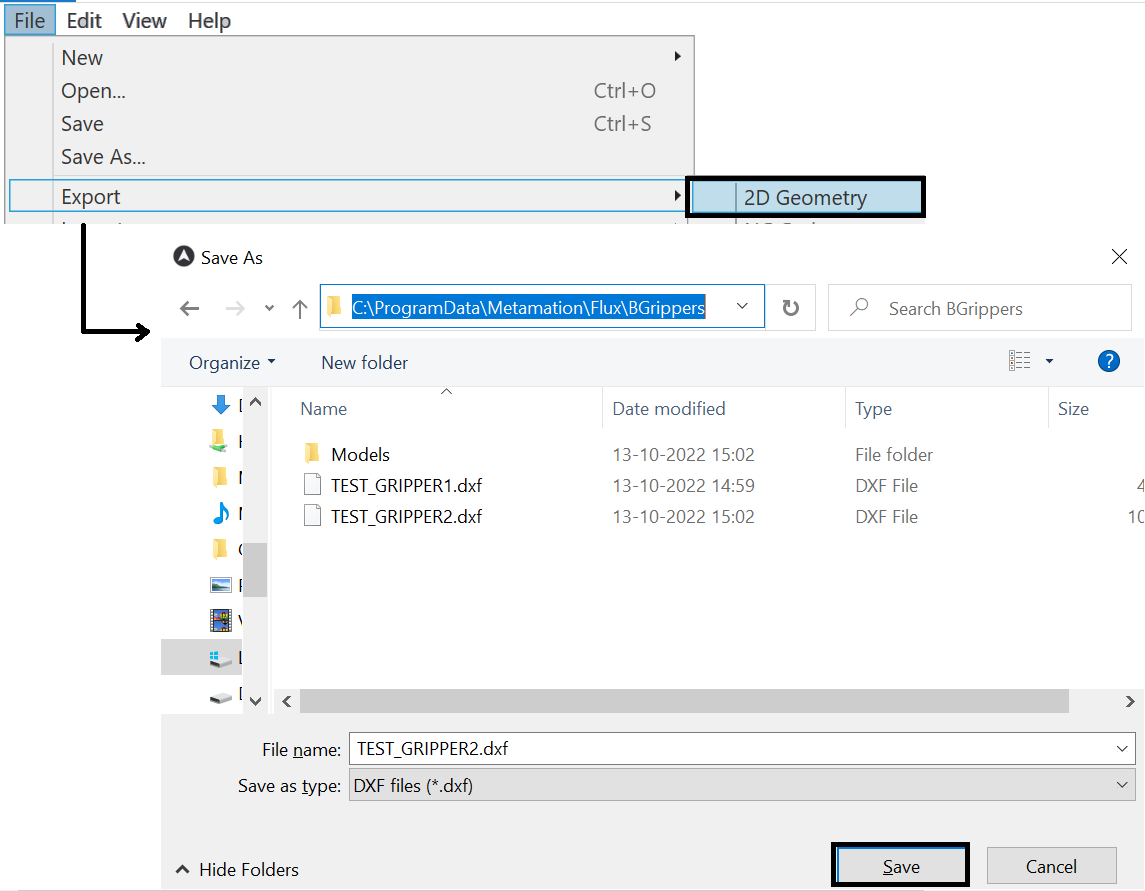

Export as DXF file under the below mentioned path after updating the text parameters from the drawing module.

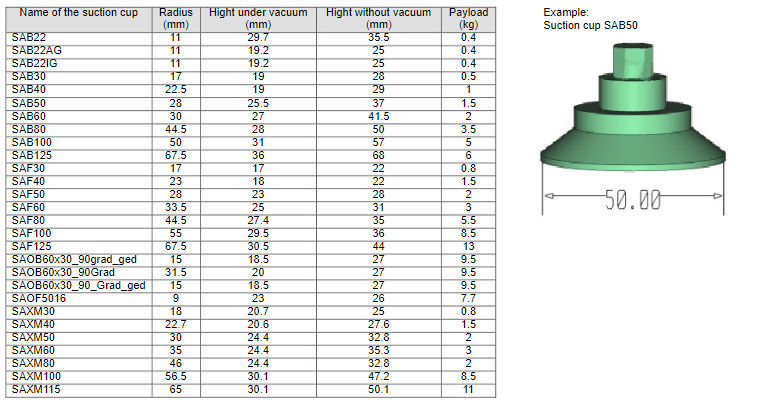

Suction Cup Types

In the Bend database there are different types of suction cups available, which can be used when configuring a new gripper.