Tools/Machine tonnage check

Does Flux check the tonnages of punches/dies and the machine?

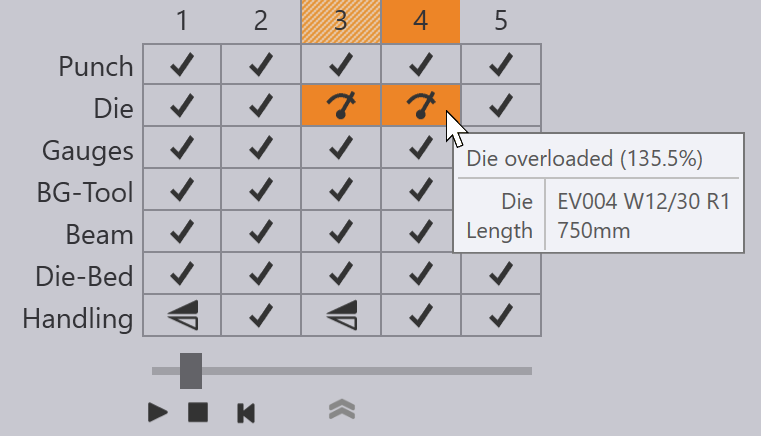

Flux computes[1] the press-force required to process each bend, and then uses this to check that the punches, dies and adapters used for the bend are not overloaded. Typically, tonnages for bend tools are specified as kN/m (kilo-newtons per meter) or tons per meter. Flux computes the linear tonnage required for a bend and checks if this limit lies within the tools' limit load. When this is violated, errors are displayed:

In addition, the total tonnage required for the bend is checked against the tonnage the machine can generate, and when the machine is overloaded, an error is displayed in the Ram row of the bend navigator.

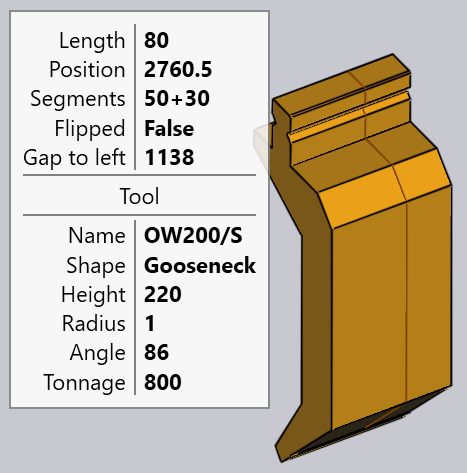

The tool-tip generated for a punch or die shows the linear tonnage that the tool is capable of handling:

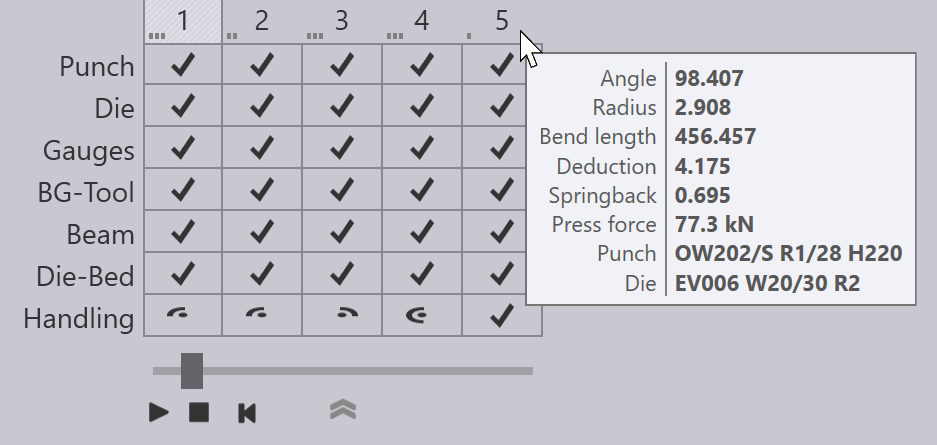

The tool-tip for a bend operation shows the overall tonnage that is required to complete the bend: