Part Pickup: Using a Blank Dispenser

Small parts are handled using a mechanical gripper, also known in Flux as a jaw gripper. If the part is smaller than about A4 size, Flux will automatically switch to using a jaw gripper. This gripper can only pick up parts from a dispensing station (also known as the blank dispenser).

Various settings are used to control this process:

-

The position and orientation of the dispenser in the machine cell.

-

The orientation of the part on the dispenser.

-

The position and orientation of the jaw gripper on the part.

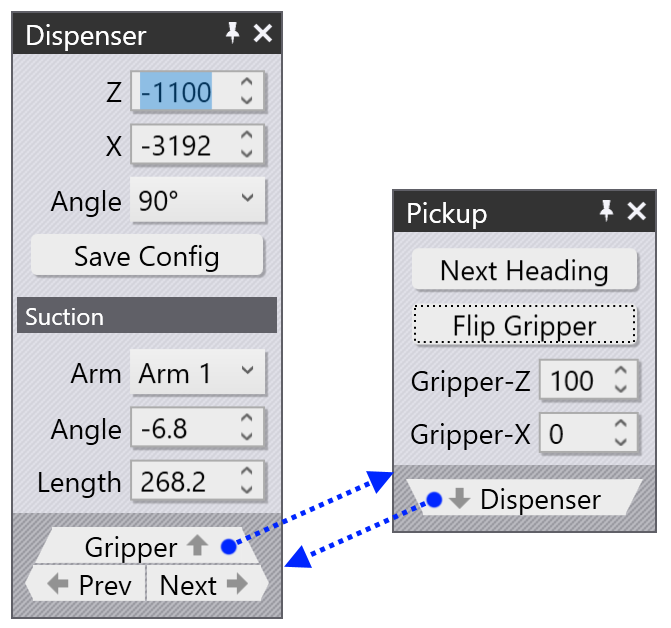

These settings are controlled using the Dispenser panel and the Pickup panel. Click on the part dispenser to open the Dispenser panel. Click twice on the P (pickup) cell on the navigator to open the Pickup panel. Alternatively, you can also click on the gripper, when the pickup stage is selected. The panels are interconnected as shown alongside.

Dispenser Panel

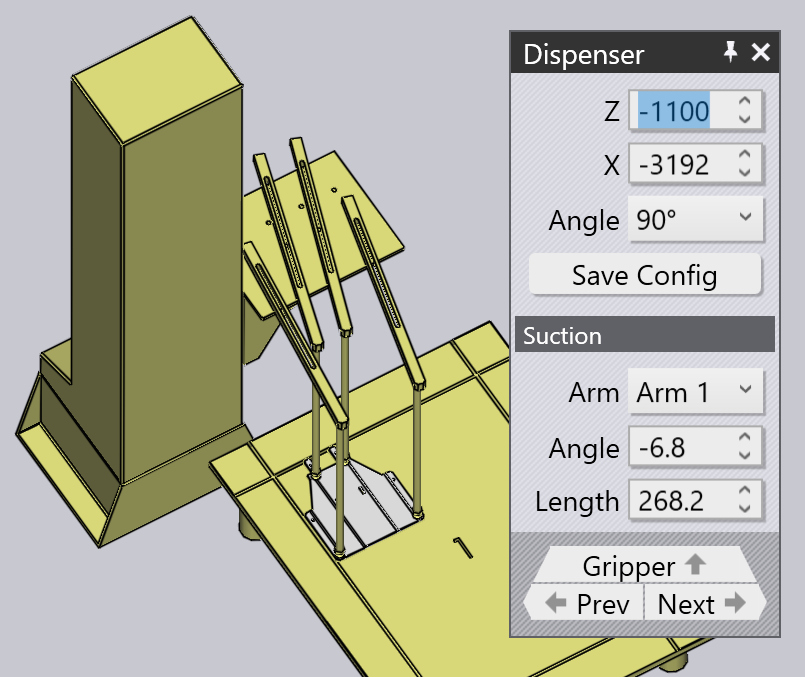

This panel opens when you click on the dispenser. Flux has automatically placed the part on the top left corner of the dispenser (where the alignment rules are) and has also positioned the suction gripper arms at the corners of the part. You can edit the arm configuration, and the dispenser location using this panel (the part position cannot be changed, it must always be aligned to the top left corner).

-

Use the Z, X and Angle settings to control the position and orientation of the dispenser, to make it match the actual position in the cell.

-

The Suction section is used to control the suction arm configuration.

-

Once an arm is selected, you can use the Angle and Length settings to move it. Flux does not actually check that the arm suction cups are lying on the part (because this configuration does not actually appear in the NC code, and it is up to the operator to configure the arms in the correct manner).

-

Click on the Gripper link to edit the part orientation and gripper position.

Pickup Panel

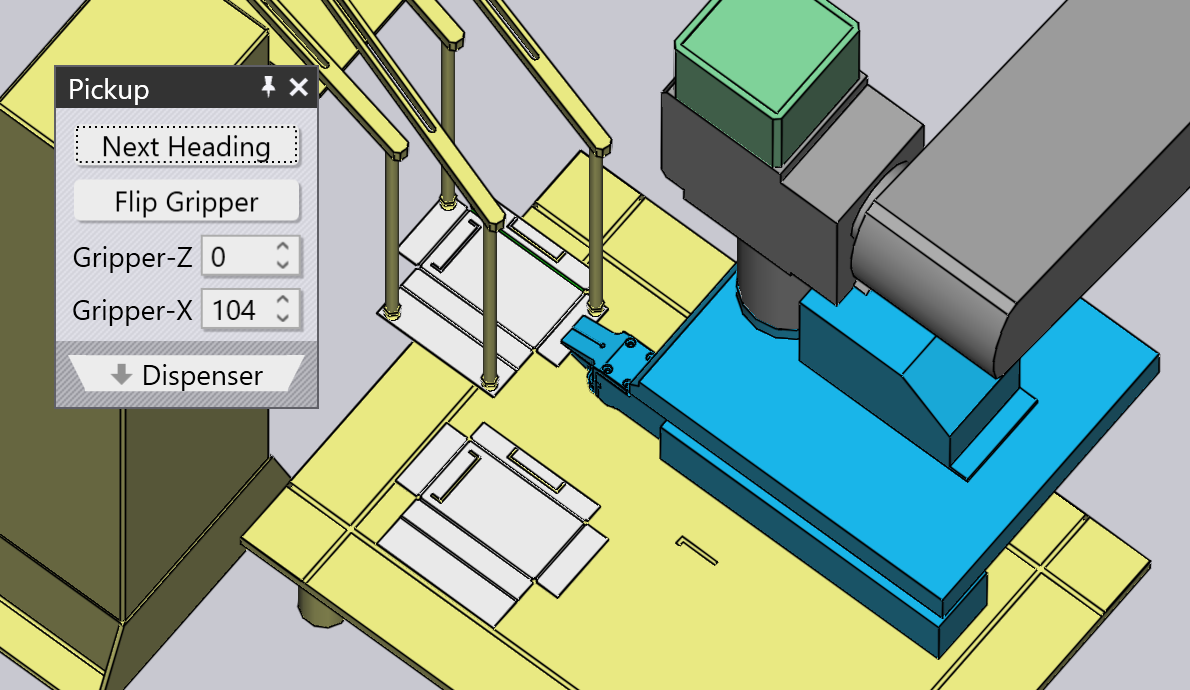

This panel is used to control the part orientation and the position of the gripper on the part.

-

Use the Next Heading button to have the gripper pick up the part from a different side. The gripper always approaches from the south side of the gripper (relative to the local gripper orientation) so the only way to do this is to actually rotate the part lying on the dispenser.

-

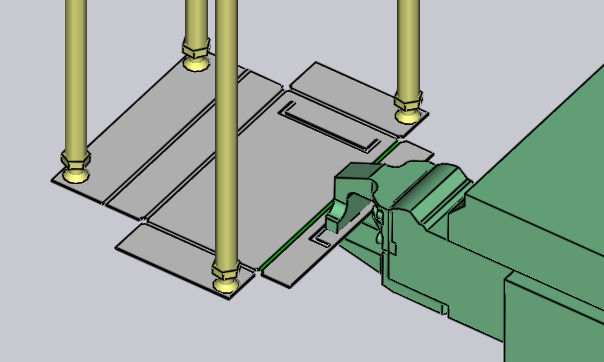

Use the Flip Gripper to rotate the gripper neck 180 degrees (so the fixed and moving halves of the gripper jaw go to the other side). For example, here is the same part as above after we have clicked both Next Heading and Flip Gripper. The part is rotated (always in steps of 90 degrees), and the gripper flipped over (so the moving part of the jaw is now above the part).

-

The Gripper-Z and Gripper-X settings are used to fine-tune the gripper position, moving it slightly more on the part.

As you make these changes, Flux computes the collision status of the gripper with the punch, the die, the part, and other components in real time for all bends and displays this in the navigator on the top. Thus, it is very easy to try different gripper positions, with immediate feedback.