Track Setup

Flux needs to know the exact position of the bend-master relative to the machine zero-point, and also needs to know the extents of the robot linear movement track. Since these are critical parameters that should not be changed by mistake, Flux must be in admin mode before you can make these changes.

-

Start Flux in admin mode by using a command line like

Flux.exe -admin. When Flux is running in admin mode, you will see an indicator on the document tab, as shown here:

-

If the BendMaster machine you need is not yet installed, install it using the Database/Machine List command from the command-bar on the left.

-

Open a simple part and tool it up for this BendMaster. Once the bending solution is displayed, choose Settings/Machine Defaults from the command-bar.

-

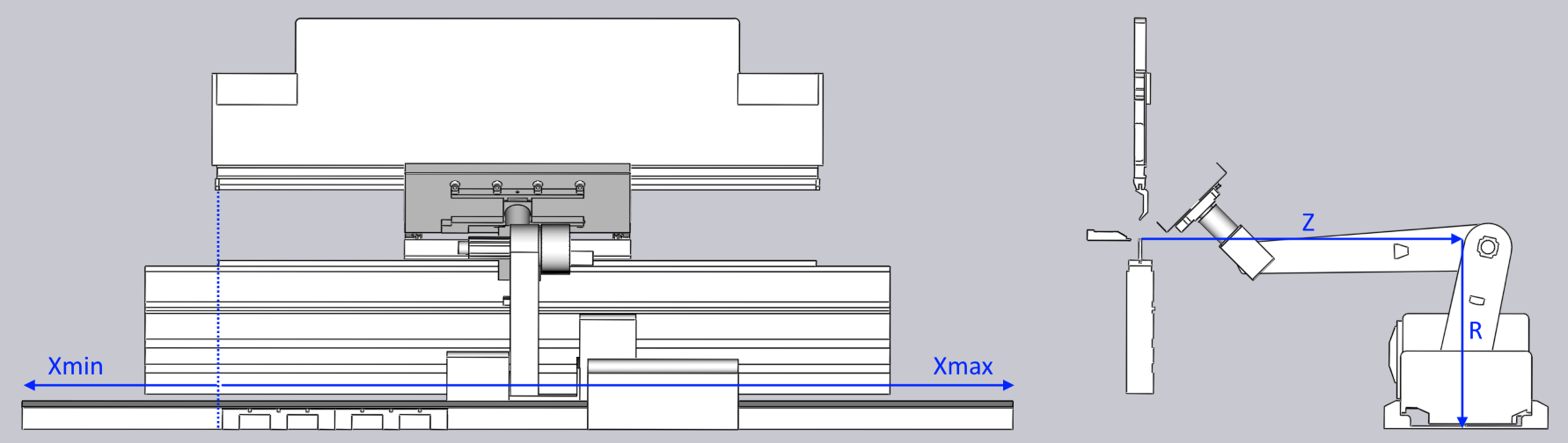

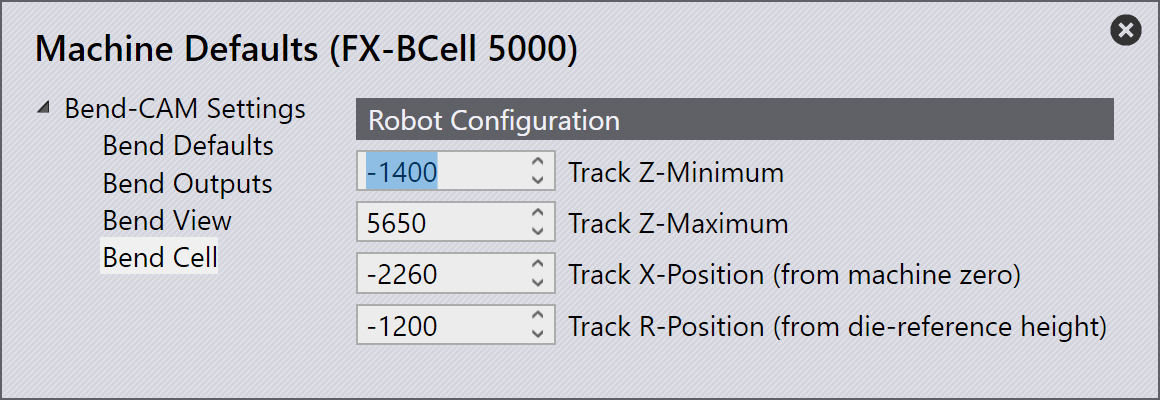

In the settings dialog that is displayed, go to the Bend Cell page. Use the values in this page to set up the track span, and also the position of the robot, relative to the bend machine (see the image below to understand these values better).

-

After you close this settings panel, restart Flux for the changes to take effect.

|

Note

|

Do not change these settings unless you are sure; entering the wrong values here will result in incorrect NC code, which can cause unexpected collisions or damage! |

The following illustration explains the different measurements used in the cell configuration settings page: