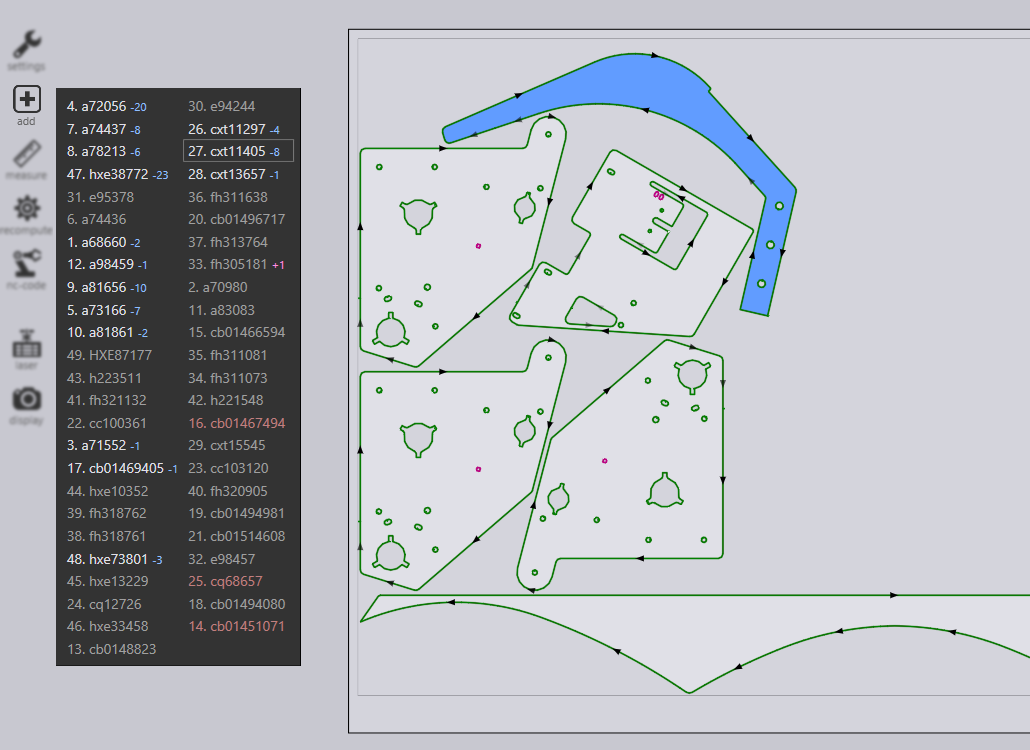

Manual Part Placement

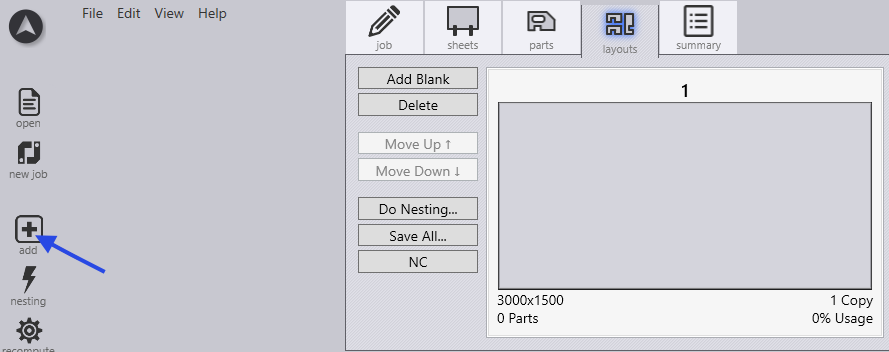

Parts in the layout can be deleted in a nest and can also be added manually using the add button.

| Appearance | Meaning |

|---|---|

|

There isn’t enough space on the layout to accommodate the part. You can still click on it. TecZone will place the part outside the sheet. |

|

Enough of this part has already been placed. |

|

This part is available for nesting. Required quantity is shown on the right with a minus sign () in front of it. When you click, software will insert the part at the previewed location and decrement the required quantity. Some other parts which can no longer be placed after placing this part will automatically turn brown as shown in the first row of this table. |

| Appearance | Meaning |

|---|---|

|

Excess copies have been placed. |

|

Required quantity of the part have not been placed. |

|

Minimum required quantity of the part has been placed, but more can be placed before reaching the maximum allowed quantity. |

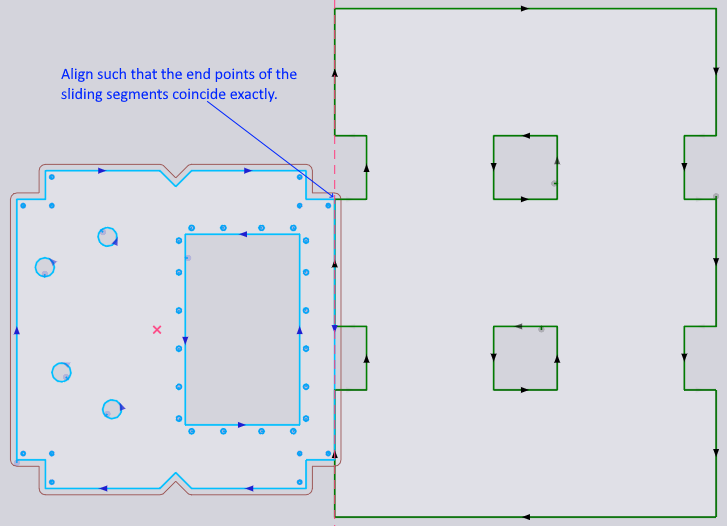

Ease of creating twinline groups with snapping exactly at kerf-width.