Avoid Retooling Pierces

Change material (from thick to thin) changes contour size but will not retool holes that were pierced.

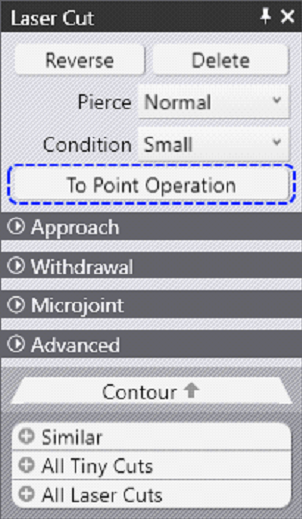

Processing of such tiny contours has changed considerably since this case was created. Currently, when auto tooling a part, the software never approximates a tiny contour with a point operation (pierce) no matter how small it is for that LTT. However, if it is smaller than the smallest size prescribed in LTT, a warning is show in the sequence table. Selecting such a cut, an option to convert the path operation to point operation is provided for the user.

After such conversions, if the user later changed the LTT or material thickness, the software automatically evaluates and converts any such point operations to path operations if it is safe. A message is shown at the bottom left of the screen indicating how many such conversions were made.