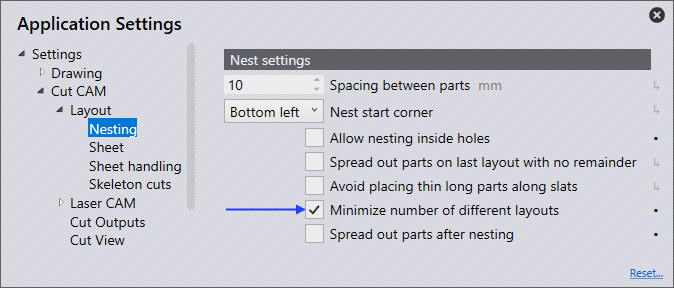

Minimize Number of Different Layouts

It is desirable to have fewer number of different layouts computed by the nesting engine. That is, create layouts whose repeat count is high. This is like a secondary goal to the nesting engine. TecZone Laser has the option to direct the nesting engine to minimize number of different layouts, possibly at a slight decrease in nesting efficiency.

For a sample job, below you can see how this setting effects nesting results.

Without this option checked:

With this option checked:

In the second case (option checked) there are fewer number of different layouts (just 2, compared to 5 previously). However, you can see that the size of the remainder sheet on the last layout is smaller.