TwinLine

TwinLine leads to significant saving in terms of machine time and material usage. Slight marks of TwinLine could be seen on the edges. Basic strategy see Basic operations → TwinLine. However, the challenge has been to ensure stability of the twinlined parts on the slat pins. Ability to automatically add microjoints to twinline groups, based on stability/tilting analysis will be highly appreciated. TecZone comes with several options to create stable twinline groups.

-

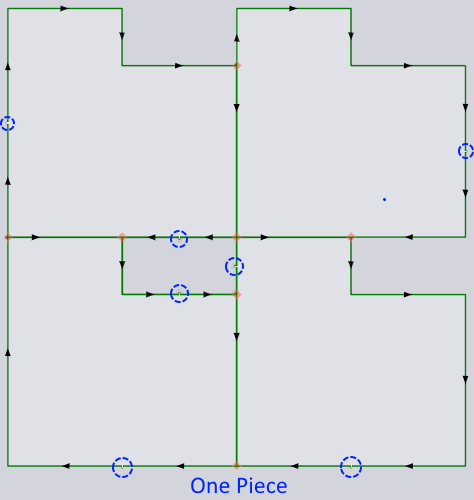

One piece: In this strategy the software will add microjoints such that the whole block, including any islands, remains attached to the sheet as a single piece.

-

One free piece: Creating a twinline block tooling that holds up as a single piece not bound to the sheet skeleton. That is, there are no microjoints on the outer contour. Only on the islands and twinline edges.

-

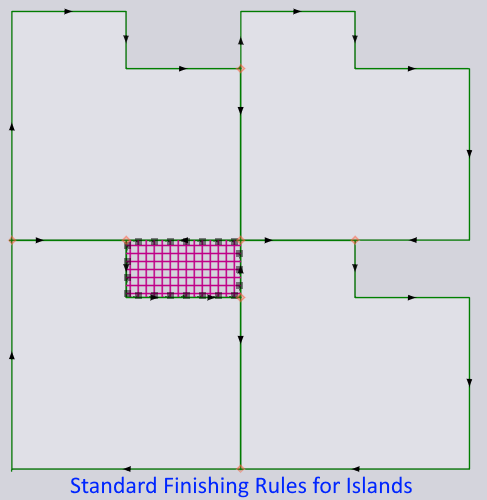

Standard finishing rules: Standard finishing rules are applied to islands. Tipping and stability analysis will be done for islands and if the finishing rules prescribe microjoints, microjoints will be added and if they prescribe scrap-tooling, scrap-tooling will be applied (and the entire island will be broken down.)

Auto Selection between Safety and Easy Strategy

It is necessary for the software to support both the safety and easy strategy of twinline tooling. But TecZone goes a step further and can analyse and automatically choose the right strategy for any given twinline group.

There are three strategies:

-

IO (TwinLine-Island-Outer) strategy: In this strategy, the software will create three different kinds of tooling paths from a twinline block.

-

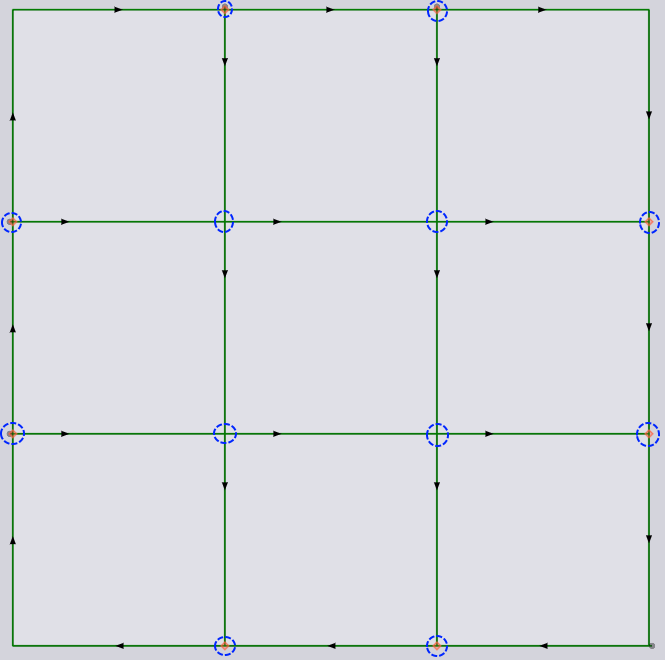

TwinLine: These are the twinline paths between overlapping edges of the adjacent parts. These are always open paths. Once the software detects these paths, they are cut first, before any other path.

-

Island: These are sheet skeleton islands formed between parts in the blockThese islands are cut next. Islands are always closed contours. Cutting of island always begins at a node that is already touched by a twinline path.

-

Outer: There will always be one outer contour for a twinline block. This is always cut at the endThe software will approach this outer contour from the left-bottom or left-top, depending on the prescribed cutting direction (clockwise or anticlockwise) for outer contours in settings.

-

-

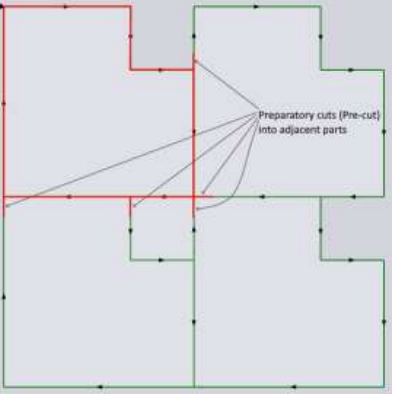

Partwise-safe strategy: This strategy is similar (probably not identical) to the safety strategy of Trutops/BoostIn this strategy, cutting progresses to next part only after the current part is cut completely free. At junction nodes where adjacent parts touch, preparatory cuts are made. The purpose of these preparatory cuts is to avoid laser head coming close to a part that is already cut (and possibly tilting).

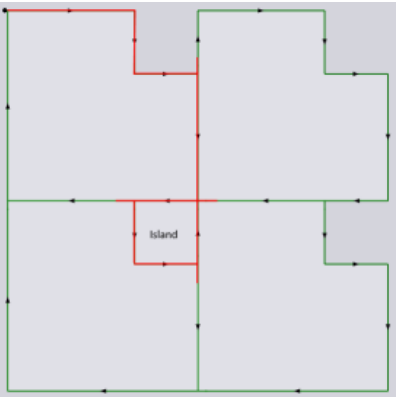

The software, when on islands, instead of just doing a precut, it completely cuts the island free as shown in the below. If this is not done, when processing the last part, it possible that the entire block is cut free before some inner islands are cut free.

-

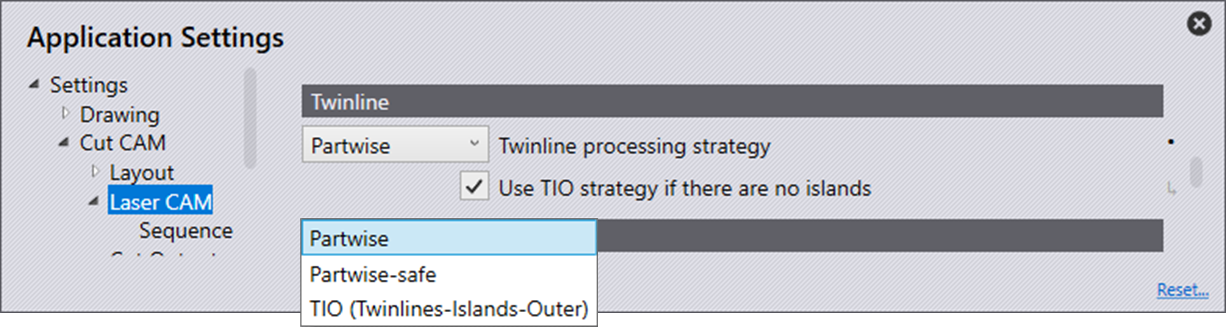

Partwise strategy: This strategy is similar to partwise-safe strategy, but there are no preparatory cuts. At junction nodes, cutting for the next part will resume 1.25mm distance into the twinline path. That is, cutting will resume a little distance away from the junction node again cutting a small portion of already cut path. This seems impossible for situations where parts could tilt, hence it is recommended only for thick sheets where parts will not tilt. User can choose the preferred strategy from laser settings as shown in the screenshot below. The tooltip on the strategy explains the strategy and its applicability.

Nanojoints vs Microjoints in a TwinLine Situation

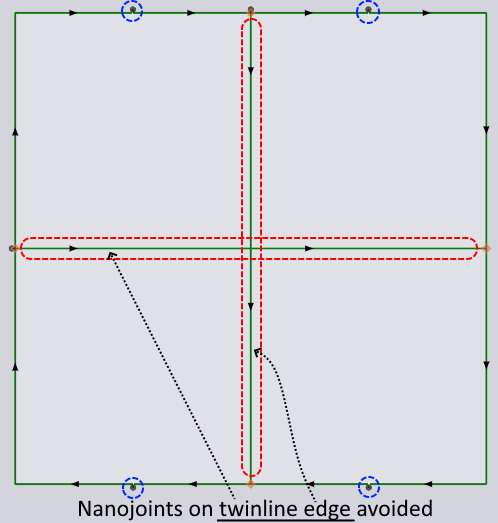

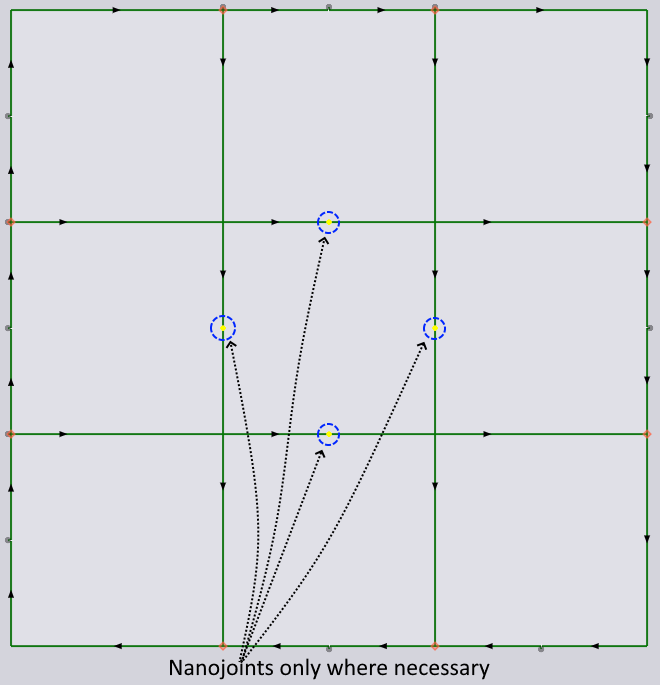

On twinlined edges, only nanojoints (or piercing on contour) are possible. On the edges of an island or outer boundary all types of joints (hard, soft, or nano) are possible. When applying the One Piece strategy, TecZone will try to minimize the number of joints on twinlined edge with the assumption that hard/soft joints (with approach path) are preferred over nanojoints (where piercing is done on the contour). Nanojoints are shown with tiny yellow dots.

| If the preferred joint type is set to nano in settings, then some joints on islands/outer would also eventually be nano joint. |

Manual microjoints for TwinLine groups

Apart from adding these microjoints automatically, the software allows for manually adding/removing microjoints anywhere on a twinline tooling by just clicking.

Slowing down at TwinLine junctions

When cutting with TwinLine easy strategy, it is better if the cutting speed is reduced when crossing over already cut edges.