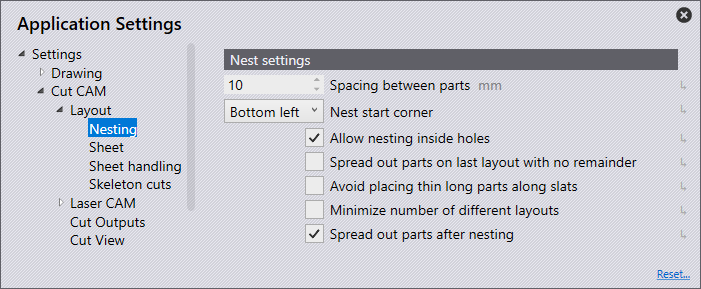

Nest Settings

Spacing between parts - This is set to the distance between each of the parts in the nest.

Nest start corner - This is the corner where the nest should start placing parts. The bottom left will nest all parts in the corner and work outwards. Other options include bottom right, top left, and top right.

Allow nesting inside holes - This option is available to allow the nesting of parts inside holes of other parts within the nest.

Spread out parts on the last layout with no remainders - This option spreads the part on the last layout by increasing the gap between parts if the remainder sheet width/height after nesting is less than the minimum remainder sheet width.

Avoid placing thin long parts along slats - This option will set the orientation of long thin parts across slats so that it is stable.

Minimise the number of different layouts - This option increases the packing as much as possible on each layout to reduce the number of sheets used.

Spread out parts after nesting -