CSV Output

Generate CSV for ERP to track which parts have been nested.

When you click on "Release NC" in Layouts tab, apart from creating NC and reports, the software exports a CSV file listing the parts produced in the job. An ERP software could read this file to update the status of order in its system.

In Application setting navigate to CutCAM → LaserCAM → Cut outputs to modify the folder destination where the released-parts CSV will be saved.

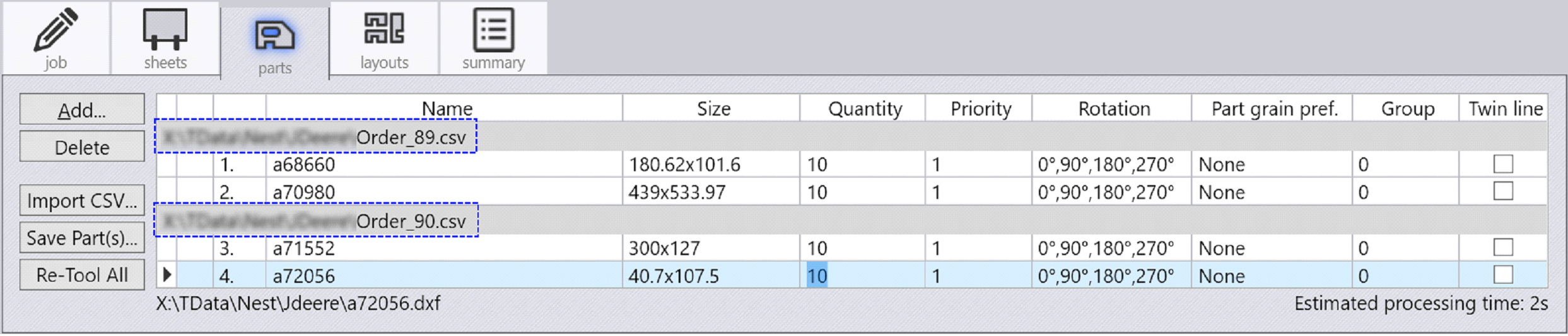

The exported CSV file contains a column which indicates the CSV file from which that part was added to the job. Depending on the workflow at the end-user, this information might be important for the ERP system. Further, parts are grouped as per their CSV origin. See the image below: