Sheet Handling

Based on the user preference, the parameters to handle a sheet can be modified in Sheet Handling.

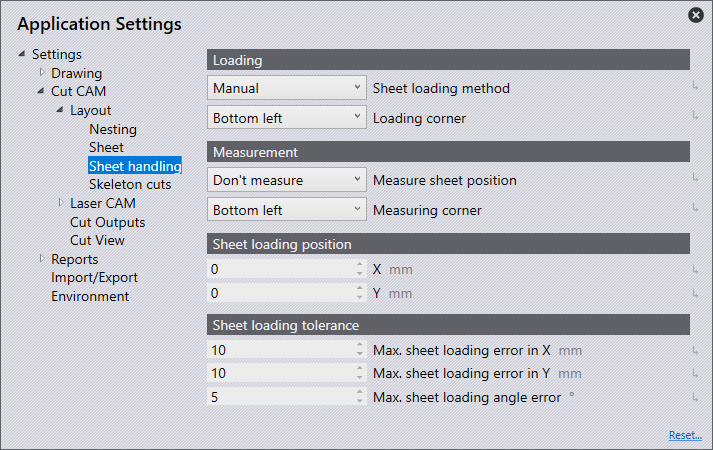

Navigate to Application Settings → Cut CAM → Layout → Sheet handling.

Loading

Sheet loading method - Depending on the machine and extras, this option is to set up how a sheet will be loaded onto the machine. The options include;

-

manual

-

pallet changer

-

various options for Lift Master

Loading corner - This option is used to set up which corner of the sheet will be loaded into the machine first when using a lift master. The options include;

-

Bottom left

-

Bottom right

-

Top right

-

Top left

Measurement

Measure sheet position - This option is used to set up whether the sheet is to be measured. The options are either;

-

don’t measure

-

with height regulation

Measuring corner - When the measure sheet position is set to 'With height regulation', this setting is used to set up where the sheet will be measured from. The options include;

-

Bottom left

-

Bottom right

-

Top right

-

Top left

Sheet loading position

X & Y -These settings are used to set up the sheet loading position in the X and Y axis of the machine. This can be between 0 > 10000 millimetres.

Sheet loading tolerance

Max. sheet loading error in X - Maximum error in loading the sheet on the table along the X direction.

Max. sheet loading error in Y - Maximum error in loading the sheet on the table along the Y direction.

Max. sheet loading angle error - Maximum angle error in loading sheet on the table.