ABOUT US

Metamation officially founded 21st May 2003, following on from an already established software development market which dated back to the mid 1990’s.

Over the years Metamation software has become a global established solution for sheet metal CAD CAM software through development of more innovative products and has worked directly with many of the leading edge machine manufacturers both in supporting the machine technologies and directly providing software solutions to end users and machine OEMS around the globe.

YEARS

0

+

NEXT GEN MODULES

0

USERS WORLDWIDE

0

's

SOFTWARE SOLUTIONS

DESIGNINED, DEVELOPED AND DELIVERED

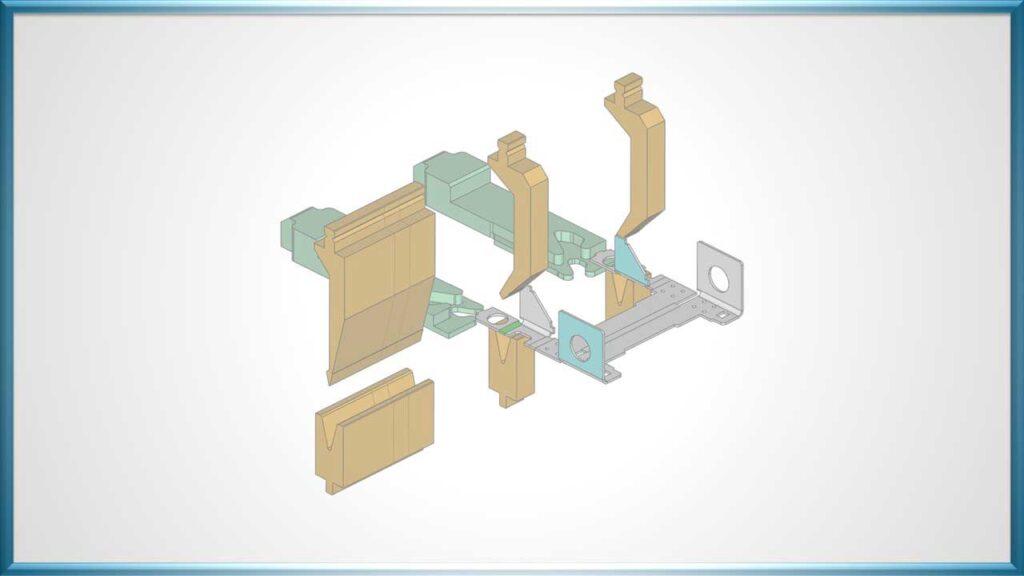

CAD Import

CAD Integration

Bending

Folding

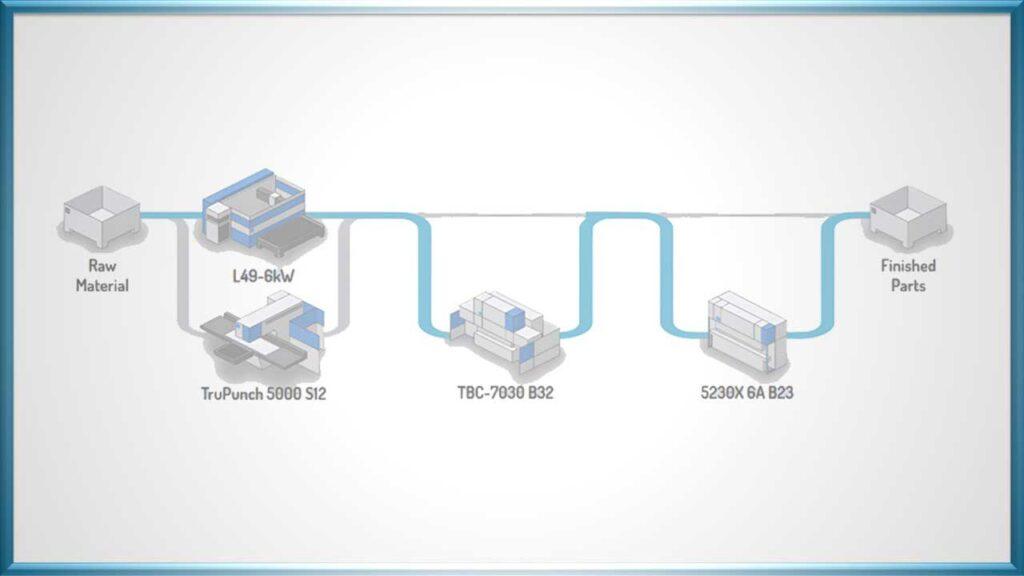

Cell

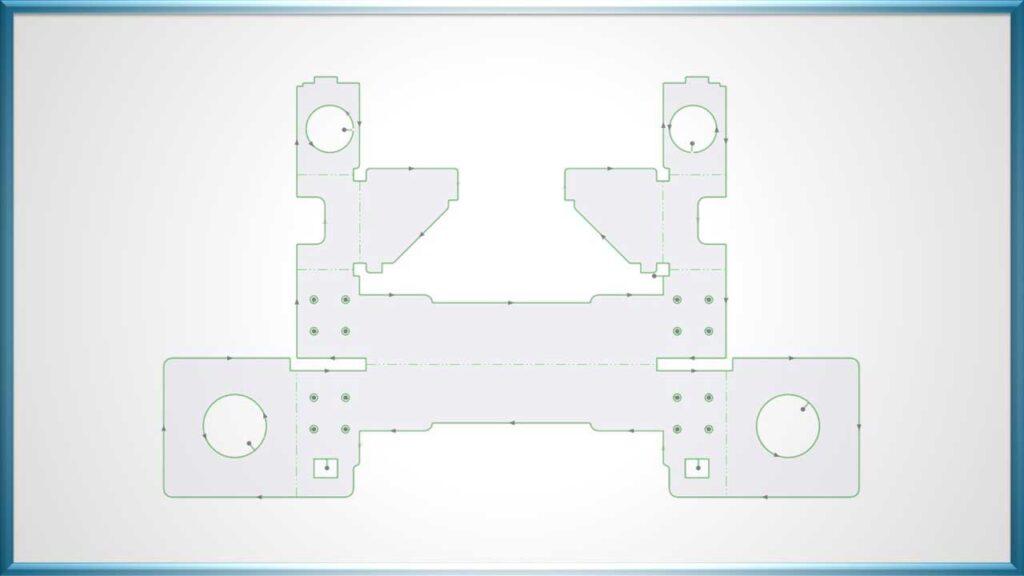

Laser

Nesting

MES

E-LEARNING AND KNOWLEDGE

Customer focused E-Learning and Knowledge Base Tutorials.

NEWS AND POSTS

Latest news and information.