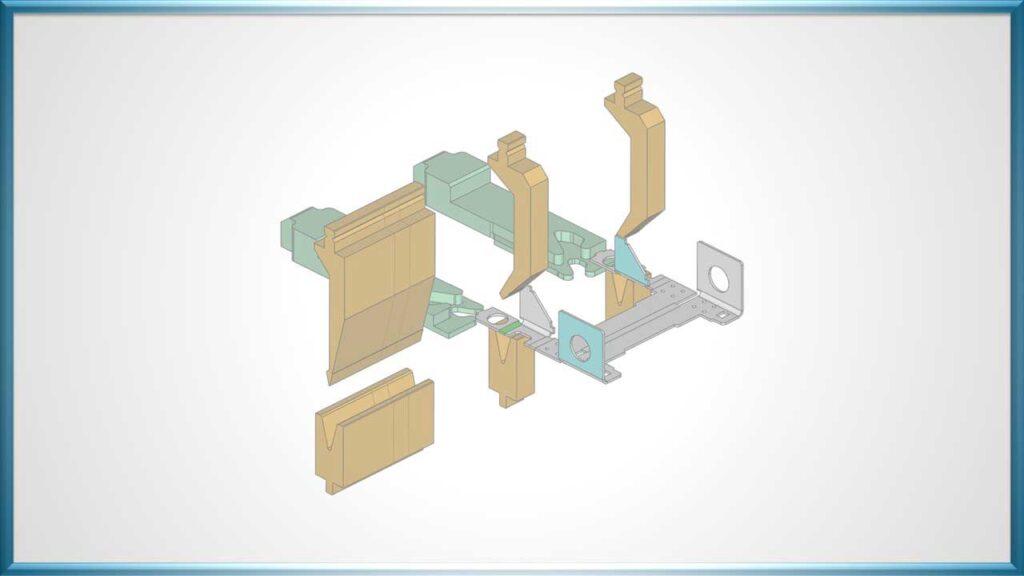

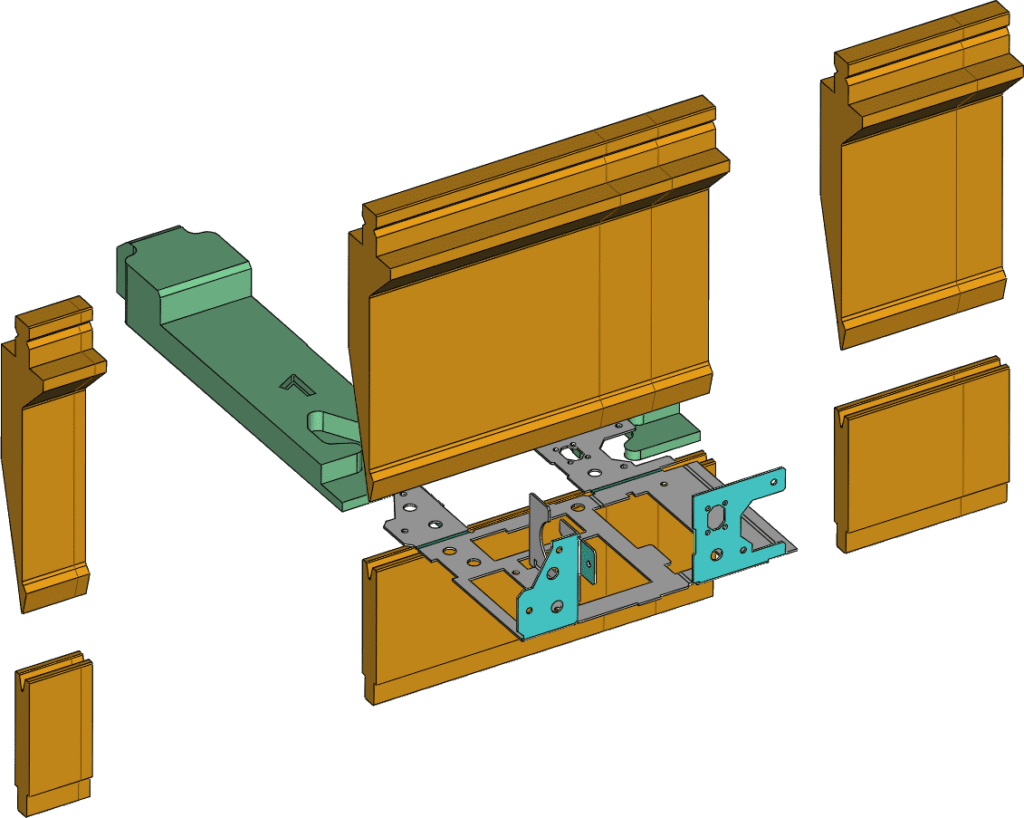

CAD FILES

Directly import or design your CAD files, with extremely quick processing of parts and assemblies.

IMPORT

Directly import native CAD files from 3D, 2D, part and assembly without the need for OLE links.

CAD CLEAN UP

Utilise features like layer mapping, geometry joining and Radius editing.

SUPPORTED FORMATS

Multiple formats supported like Acis, Dwg, Inventor, Catia, Dxf, I-Deas, Iges, MetaCAM, SolidEdge, Pro-E and Solidworks.

DESIGN

Design through MetaCAM 3D CAD which will allow for easy and quick construction of 3D models.

ADAPTION

Smart geometry adaption allows for a higher level of accuracy when unfolding 3D CAD.

SPEED

Average import time 1-2 seconds from 3D state to programmable bend

CAD.

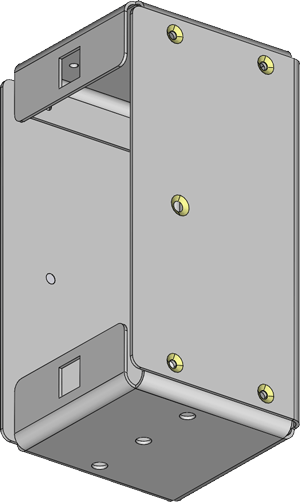

TOOLING

Flux BEND comes preloaded with thousands of tools including:

Gooseneck | Narrow Relief | Pointed | Radius | Sash | Straight | Z-Bend | FEV | Hem | Rollbend | V | VLM | 2V | Block | Classic | Punch Adapters | Punch Extenders | Punch Holders | Die Adapters | Die Extenders | Die Holders.

From many suppliers including:

Trumpf | Amada | Barus | Bystronic | EHT | Euram | Eurostamp | Fabsupply | Ferrari | Gimec | JFY | Komatsu | Kyokko | Mate | Rolleri | Technsotamp | Toyokoki | UKB | Wila | Wilson.

CATALOGUES

Currently preloaded with over 50 catalogues of tooling all availble for selection.

CUSTOMABLE

Import your own tools with the ability to export existing tools and modify them.

PRIORITIES

Ability to set priority levels to help favour the outcome of automatic tooling.

STYLES

Over 20 styles of punch's, die's, punch and die holders and adapters supported.

INVENTORY

Complete control over your press brake inventory with standard and custom segment lengths.

COLLECTIONS

Create custom collections of tooling to help pre-define customer or machine setups.

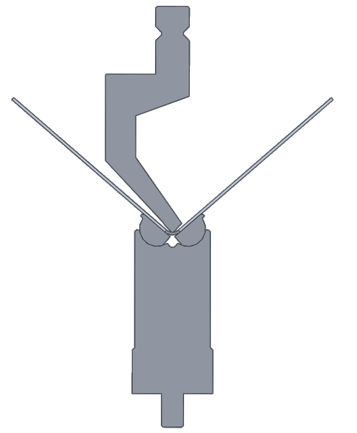

BEND SOLUTION

Intelligent bend solutions that are fully immersive allowing for easy edit.

SPEED

Complete control over your press brake inventory with standard and custom segment lengths.

VALIDATION

Create custom collections of tooling to help pre-define customer or machine setups.

REALTIME ALERTS

Realtime alerts for any type of error, from collision detection through to tool stress and hole deformation.

ACCURACY

Ability to set priority levels to help favour the outcome of automatic tooling.

ERGONOMICS

Complete control over your press brake inventory with standard and custom segment lengths.

IMMERSIVE

Ability to set priority levels to help favour the outcome of automatic tooling.