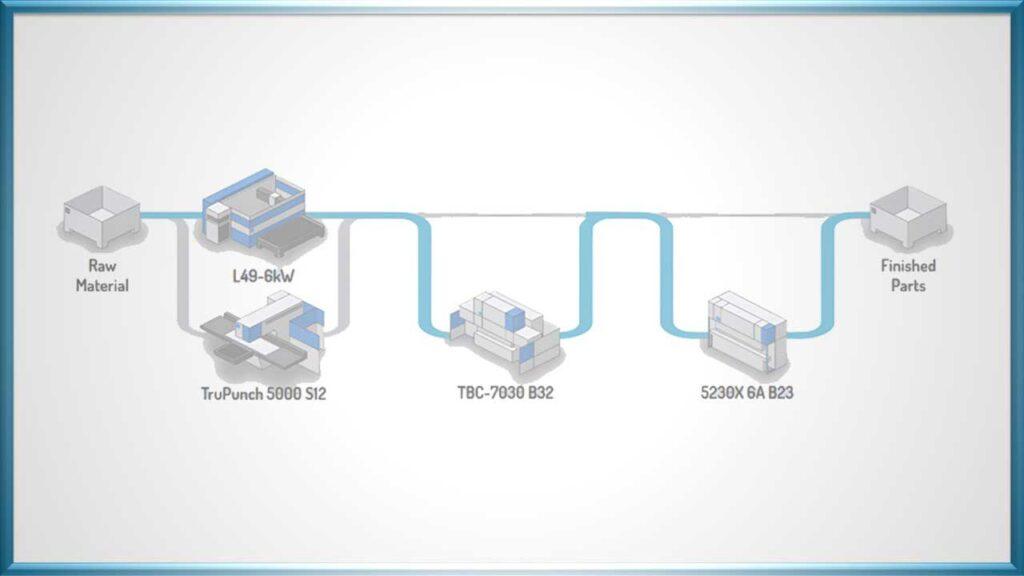

- Database Storage System.

- User Roles.

- Automated Batch Bend / Cut Tooling.

- All Stage Error Trapping.

- Highly Visible Part Validation and Information.

- Easy Edit Computed Solutions.

- Job Import or Manual Creation.

- Material and Remnant Management.

- Workflow Driven Scheduling.

- High Material Yield Nesting.

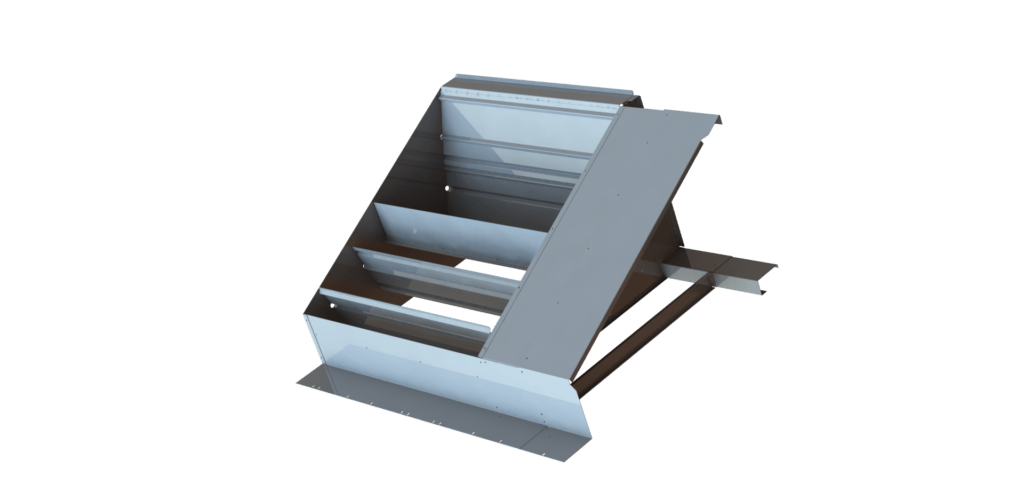

Quickly import your CAD files from a large range of built in supported formats which include many industry formats like ACIS, Inventor, CATIA, Creo-Pro/E, I-deas, IGES, MetaCAM, NX-Unigraphics, Parasolid, PRC, Rhino3D, SolidEdge and SolidWorks.

Files can be imported both in part or assemby modes, or drawn using MetaCAD 2D or 3D.

- 20+ Industry Standard Formats Supported.

- 2D and 3D File Support.

- No OLE or Additional Software Required.

- Rapid Accurate Importing.

- Part and Assembly Importing.

- One Click Assembly Explosion.

- Form Tool Mapping.

- Layer Mapping.

- Sketch Mode.

- Flat Pattern Export.

Fast, smart and highly intuitive which supports advanced bending algorithms, large built in tool and catalogue support with the ability to create custom tools. Bending is calculated and validated for any errors or warnings along with adaptive flat patterns created with NC code and setup sheets.

- Comprehensive Tooling Catalogues.

- Custom Tool Creation.

- Intelligent Bend Solutions.

- Operator Ergonomic Options.

- Immersive Edit Ability.

- Full Process Validation and Simulation.

- Standard Work Instructions.

- NC Code on Supported Controllers.

- Adaptive Flat Patterns.

- Process Optimisation.

Next generation of laser programming which features new intelligent algorithm’s that select the most optimal cutting strategy whilst being highly immersive to use.

- Rapid, Accurate Tooling and Nesting Solution.

- Comprehensive Technology Databases.

- Multiple Pierce Type Support.

- Fully Immersive Edit Capability.

- Scrap Cut.

- Optimised Fly line / Stitch Cutting.

- Hazzard Avoidance Sequencing.

- Quick Nest and Twin line Nesting.

- Smart Nesting Edit Control.

- Detailed NC Code and Reports.

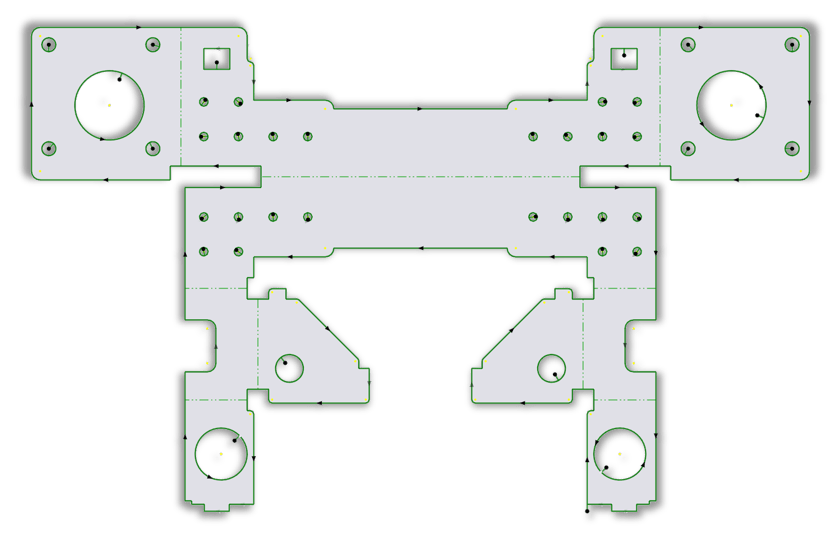

Comprehensive solution for turret and rail based machines with advanced tool support and sequencing options.

Features pre-definable tooling and sequencing styles for automatic or interactive solutions.

- Rapid, Accurate Tooling and Nesting Solution.

- Comprehensive Tooling Support.

- Automatic Tooling Solution.

- Fully Immersive Edit Capability.

- Advanced Turret and Tooling Application.

- Optimised Sequencing.

- Quick Layout Nesting.

- Job Nest Configurations.

- Tool Based Optimised Job Nest.

- Detailed NC Code and Reports.

Easy order entry with import or manual creation options that support several features like min – max quantity nesting, priorities, rotation, grain control, grouping and common line.

- Batch CAD Import.

- Product Order Import.

- Automatic Tooling.

- Tool Analysis and Warnings.

- Nest Priorities with Grain and Group Control.

- Optimised Twin Line Nesting Support.

- High Performance Nesting.

- Fully Immersive Edit Control.

- Dynamic Sheet Slice and Marking.

- Summary Reports.

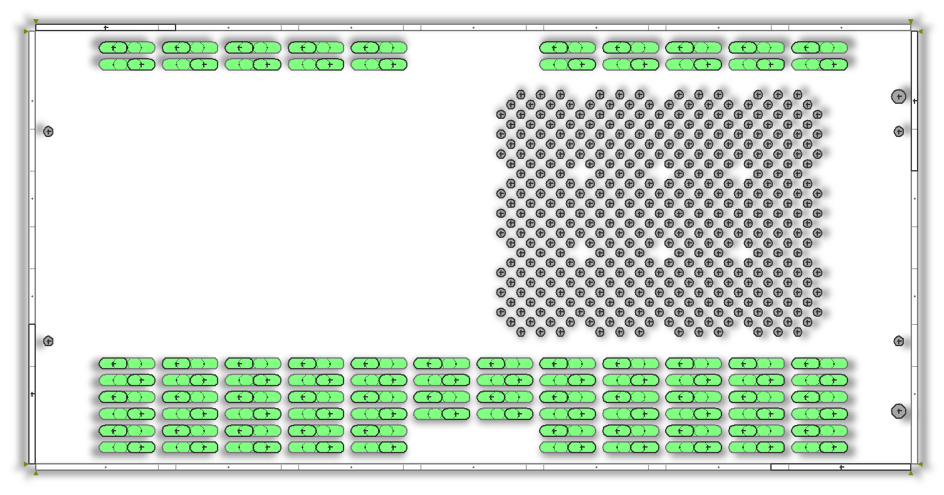

Smart nesting system generates process optimised layouts minimising overall production costs and with near total elimination of rejections.

Sophisticated algorithms compute probability of tipping of cut parts and automatically manages routes to avoid collision all of which are produced in a rapid time.

- Tool Analysis and Warnings.

- Optimal Twin Line Cut Nesting Support.

- High Performance Nesting.

- Optimal Hazzard Analysis and Adjustment.

- Fully Immersive Edit Control.

- Dynamic Sheet Slice.

- Automatic Remnant Saving.

- Remnant Easy ID Sheet Marking.

- Nc Code

- Summary Reports.