Punch Laser Nesting Software

Punch Laser Nesting Software Punch Laser Nesting Software is a fully functioning and integrated nesting solution designed for multiple technologies like Punch, Laser, Waterjet and Plasma based machines. Features include optimal nesting algorithms which can be used depending on the style and nesting you require which ranges from basic rectangular nesting through to dissimilar parts […]

Laser Tooling and Nesting Software

LASER TOOLING AND NESTING SOFTWARE Laser Tooling and Nesting Software Our next generation of laser tooling and nesting software is built from the gound up utilising years of industry knowledge and packaged in a smart and easy to use software designed to give you the accuracy, speed and results needed in todays competitive market. CAD […]

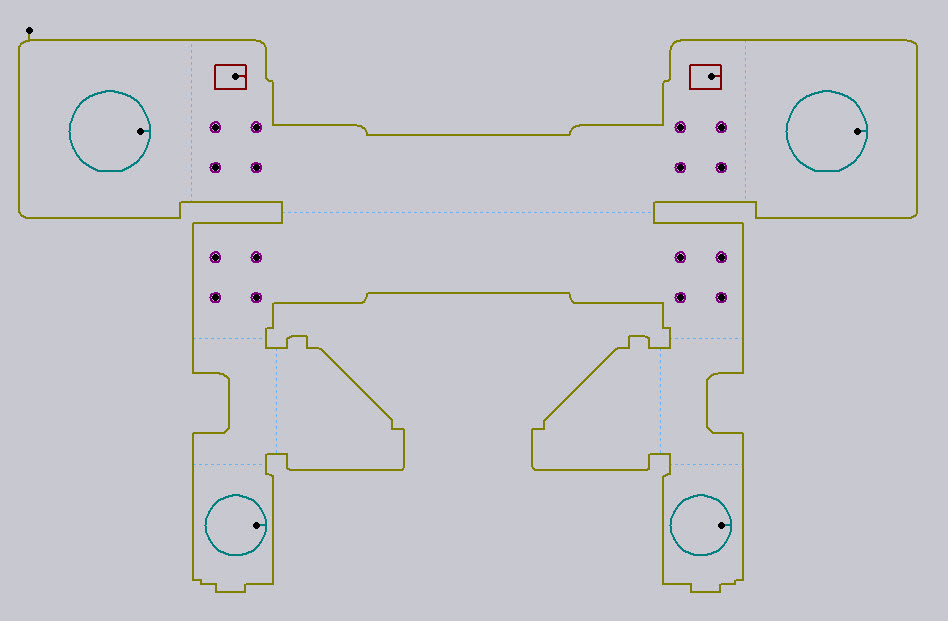

2D Nesting Software

2D Nesting Software for Punch, Laser, Waterjet, and Plasma-based machines, feature-packed and highly configurable with advanced nesting capabilities.

Machine Management and Nesting Savings

Combining nesting capability with proper machine management—scheduling, determining proper sheet size, etc.—adds efficiency to the overall production process.

CAD CAM NESTING

The business cost for profile cutting on machines has been and still is primarily driven by Front End Time, Material Utilisation, Sequence Optimisation and Customers expected delivery dates where ever increasing demands are placed on suppliers to be more flexible on batch size and with quicker turn a rounds (Sound Familiar)?

2D Cutting Software

2D CAM for Laser, Waterjet, and Plasma-based machines, feature-packed and highly configurable with advanced nesting capabilities.

Metamation Lasnek Customer Feedback

Sheet Metal CAD CAM provided to Lasnek UK, starting from punch based systems through to laser and then automation.

CEL Study using CAD CAM and ERP Automation Software.

sheet Metal CAD CAM Software Synergy

MetaCAM SolidEdge

Metamation’s CAM support for Solid Edge” Solid Edge Nest Bend integrated into Meta* range of products designed to help you easily process your Solid Edge Cad Files

CUT CAM

Profile Tooling and Nesting Software Profile Cutting Machine software is an integral part of the manufacturing process where the ability to have databases of machine cutting data along with the ability to set your own tooling rules all help play an important part of the process. The start of the workflow normally begins with CAD […]