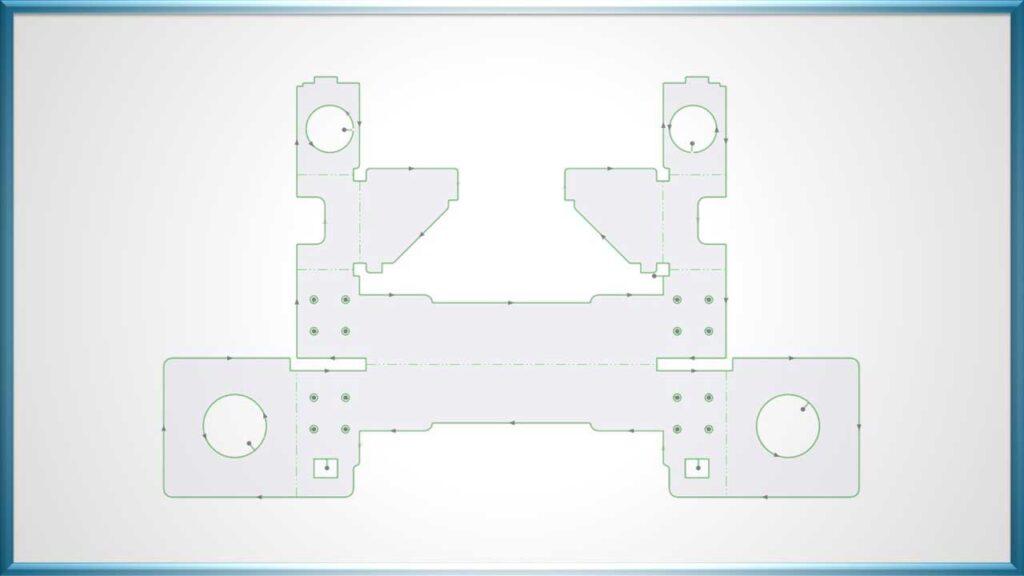

CAD AND JOB CREATION

Directly import or design your CAD files, with extremely quick processing of parts and assemblys.

IMPORT

Directly import native CAD files from 3D, 2D, part and assembly without the need for OLE links.

JOB

Import or create nest jobs.

MATERIAL

Set sheets and quantities available.

CONFIGURATION

Set key items such as priorities, material grain constraints and nesting orientation.

BATCH

Batch Tool CAD files, ready for optimal nesting.

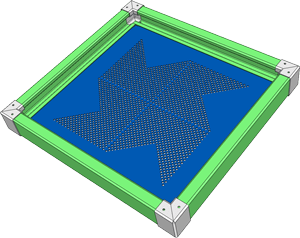

NESTING

Flexible and high performing nests based on the machine technology being used.

PUNCH OPTIONS

Optimal tool analysis options to help improve sheet packing.

REMNANT AND SLICE

Destuct sheet and Remnant control options available.

Code

Produce optimal NC Code.

SEQUENCING

Use pre-defined rules or edit on the fly to create optimal sequencing.

NEST EDIT

Fully editable nests with a suite of options for manipulating parts.

REPORTS

Configurable setup sheets for your machine operators.

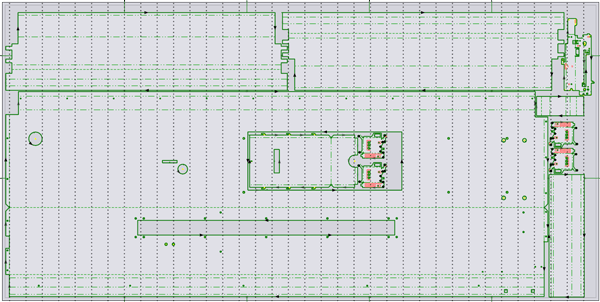

LASER UPDATED NESTING

Laser specific updates in nesting include.

RE-ARRANGE OPTIONS

Updated options for re-arranging parts on the sheet for spacing or remnant.

SEQUENCE

New optimal sequencing.

HAZZARD ADVOIDANCE

Smart automatic hazzard avoidance.

REMNANT AND MARK

Automatic remnant control with remnant marking.

ROUTE

Fully editable nests with a suite of options for manipulating parts.

OPTIMAL

Built in tilt analysis with pierce optimisation.