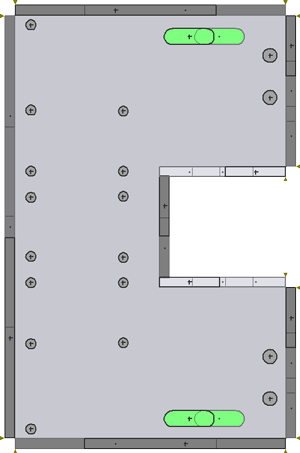

CAD FILES

Directly import or design your CAD files, with extremely quick processing of parts and assemblys.

IMPORT

Directly import native CAD files from 3D, 2D, part and assembly without the need for OLE links.

DESIGN

Design through MetaCAM 3D CAD which will allow for easy and quick construction of 3D models.

CAD CLEAN UP

Utilise features like layer mapping, geometry joining and Radius editing.

ADAPTION

Smart geometry adaption allows for a higher level of accuracy when unfolding 3D CAD.

SPEED

Average import time 1-2 seconds from 3D state to programmable CAD.

SUPPORTED FORMATS

Multiple formats supported like Acis, Dwg, Inventor, Catia, Dxf, I-Deas, Iges, MetaCAM, SolidEdge, Pro-E and Solidworks.

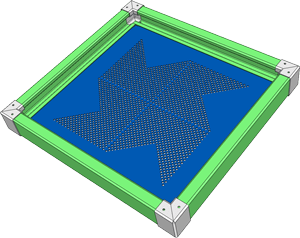

TOOLING

Smart punch tooling module, with high levels of configurability.

TOOL DATABASE

Create standard tools and custom tools including cluster, wheel deburring and many more.

TOOLING

Automatic, interactive and manual tool options are a few of the extensive options.

SEQUENCING

Built-in configurable sequencing options which include grid, staggered hole and belt.

AUTOMATION

Support for material loading and part removal systems with automatic placement options.

NESTING

Manual, interactive and automatic Nesting which has additional features for punch machines.

VISUAL

Change the visual display options for tools using colour codes for easy identification.

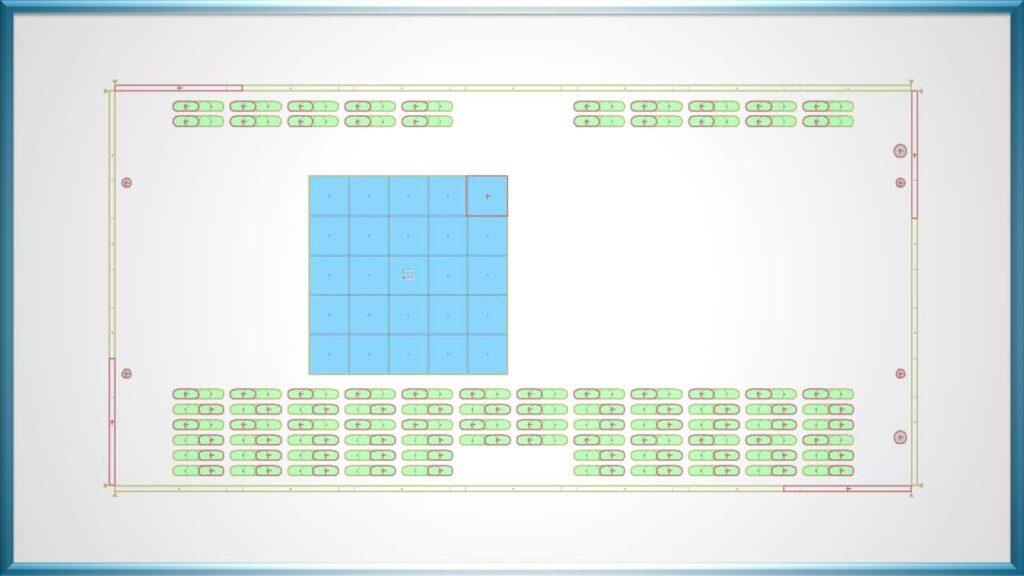

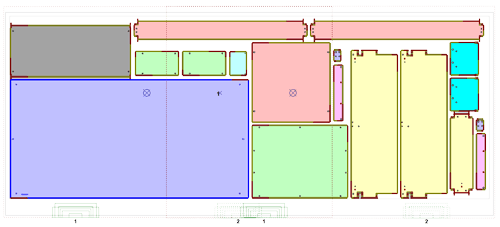

NESTING

New generation nesting engine that is designed to produce high yield nests foregoing extensive nesting times.

LAYOUT

Quickly take a part from a tooled state to a single sheet nest.

DYNAMIC

Next generation algorithms for smart nesting and part placement.

IMMERSIVE

Fully interact wilth all areas of the parts and nests.

SEQUENCE

Punch optimised sequencing and repositioning control with easy edit options.

JOB

Create complex job based nests with additional priorities and grouping options.

IDENTIFICATION

Easy identification of parts with configurable colour coded setup reports.