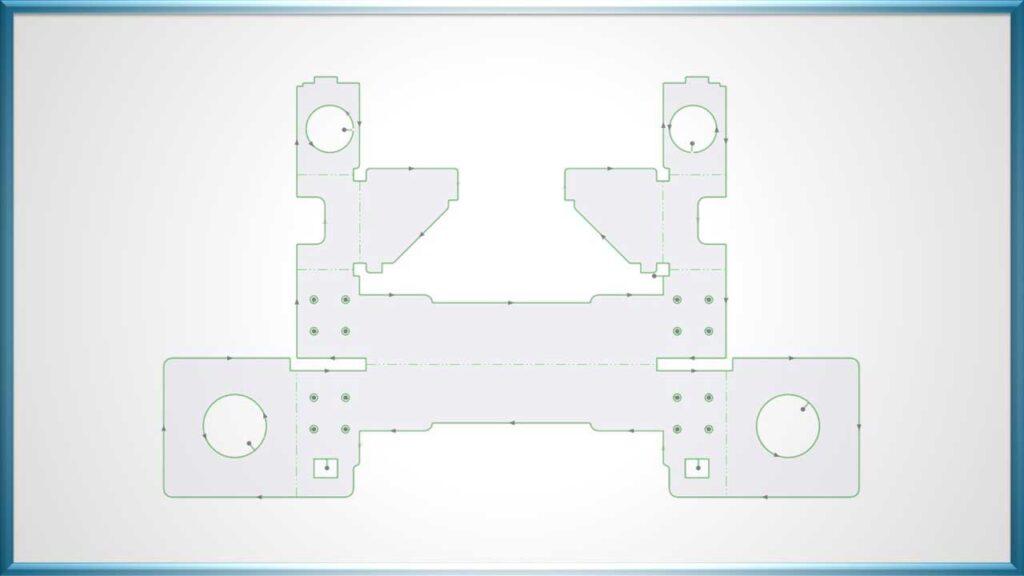

CAD FILES

Directly import or design your CAD files, with extremely quick processing of parts and assemblies.

IMPORT

Directly import native CAD files from 3D, 2D, part and assembly without the need for OLE links.

DESIGN

Design through MetaCAM 3D CAD which will allow for easy and quick construction of 3D models.

CAD CLEAN UP

Utilise features like layer mapping, geometry joining and Radius editing.

ADAPTION

Smart geometry adaption allows for a higher level of accuracy when unfolding 3D CAD.

SPEED

Average import time 1-2 seconds from 3D state to programmable laser CAD.

SUPPORTED FORMATS

Multiple formats supported like Acis, Dwg, Inventor, Catia, Dxf, I-Deas, Iges, MetaCAM, SolidEdge, Pro-E and Solidworks.

LASER TOOLING

New generaration laser tooling engine that has smart tooling rules and complete edit / adjustment functionality.

LASER DATABASE

Detailed and comprehensive technology tables gives the tooling assignment more accuracy.

DESTRUCTION / TAG

Optimal settings for feature destruction and tagging to prevent tipping and head crashes.

SEQUENCING

Sequence optimisation will plot the best path for cutting whilst taking into account the part features.

TOOLING

Automatic tooling assigns correct lead in, pierce, approach settings and stitch cut.

PIERCE

Multiple technology driven pierce types available which are automatically assigned.

IMMERSIVE

Fully interact with all the tooled features and make any changes you may require.

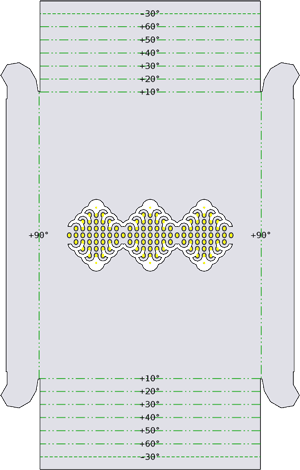

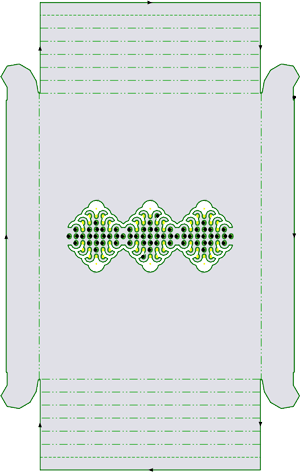

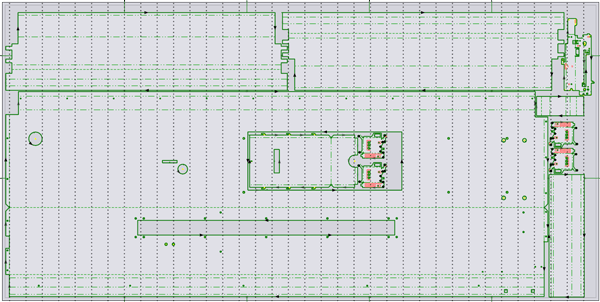

NESTING

New generation nesting engine that is designed to produce high yield nests foregoing extensive nesting times.

LAYOUT

Quickly take a part from a tooled state to a single sheet nest.

DYNAMIC

Next generation algorithms for smart nesting and part placement.

IMMERSIVE

Fully interact wilth all areas of the parts and nests.

DISSIPATION

Heat dissipation sequencing supported.

TILT ANALYSIS

Smart analysis can alter the sheet to avoid tilt / position problems.

SEQUENCING

Optimal sequencing designed to save time and prevent problems.